huide

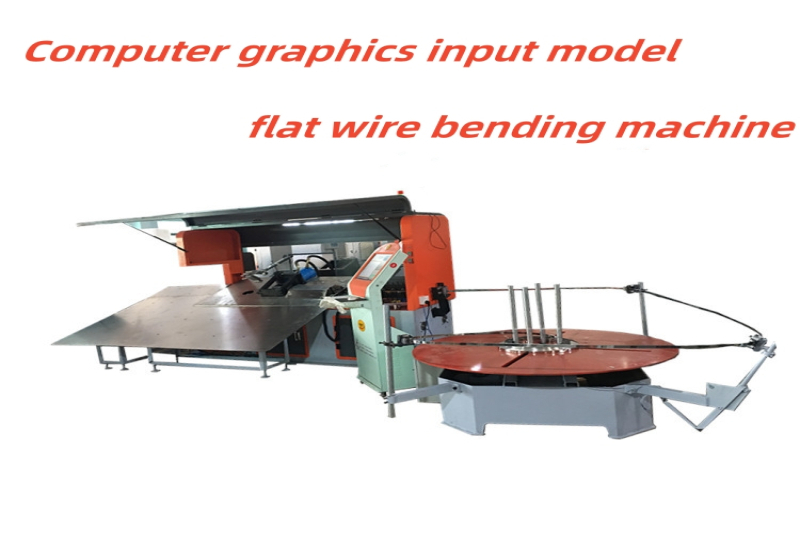

wire rotating forming machine

| Place of Origin | China |

| Condition | New |

| Machine Type | wire rotating forming machine |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump |

| Weight (KG) | 2876 |

| Key Selling Points | Competitive Price |

| Warranty | 1 years |

| Applicable Industries | float decoration |

| Raw Material | Carbon steel, SS |

| Material / Metal Processed | ALLOY |

| Product name | wire rotating forming machine |

| Keyword | fish hook wire bending machine |

| Wire diameter | 18.15mm-9.8mm |

| Wire type | Square, Round wire bending |

| Marketing Type | Ordinary Product |

| Payment terms | 30%T/T in advanced payment,the left payment should be paid after we finish our production.( we will take machine and packing photos for your checking ) We have our own forwarder. We can check the delivery information timely. |

| Packing | In standard export wooden case for wire bending Machine Delivery time:within 15 days after receiving your |

| Wire forming machine is suitable for various metals | (such as steel, iron, stainless steel, aluminum wire, etc.) |

| Features | Twisting head is designed in copper tube transport, more stable and stronger than bearing transfer Technical parameters(3d cnc wire bending machine supplier) |

Three groups of strong feeding-wire roller subassemblies powered with a servomotor ensure accurate wire feeding and excellent straightening.

HUIDE( Fengsheng )Machinery Integrity management Fine workmanship professional team

Graphic input rotary head 3D wire forming machine composition and structure

china wire bending machine manufacturer-OEM/ODM service is available. Low MOQ, we can accept low MOQ as 8 sets, or even less quantity for every single item in big production order. We have full experience in exporting and project management, to secure your order 100%.

wire rotating forming machine services FAQs Guide Are you looking for a quick review guide about wire rotating forming machineservices? An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding wire rotating forming machine services. Let’s continue!

2.What is the expected lifespan of a wire rotating forming machine?

3.What are the advantages of using a wire rotating forming machine over manual bending methods?

4.About the development history of wire rotating forming machine factory

5.About wire rotating forming machine origin

6.About wire rotating forming machine overseas warehouse

7.About wire rotating forming machine payment method

8.What is the maximum thickness of material that can be bent using a wire rotating forming machine?

9.About wire rotating forming machine delivery date

10.What materials can be bent using a wire rotating forming machine?

11.Does the size of the wire rotating forming machine affect its capabilities?

12.What factors should be considered when choosing a wire rotating forming machine for a specific application?

1.Are there any limitations to the types of shapes that can be bent with a wire rotating forming machine?

We are a professional wire rotating forming machine company dedicated to providing high quality products and services. Yes, there are limitations to the types of shapes that can be bent with a bending machine. The type of material, thickness, and size of the material will all affect the types of shapes that can be bent. Additionally, the type of bending machine used will also affect the types of shapes that can be bent. Wires with a diameter less than 0.5mm are easily deformed by the machine during processing. If the bending R angle is particularly small, it needs to be processed on a spring machine.

2.What is the expected lifespan of a wire rotating forming machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. There are two main factors that affect the service life of line forming equipment: one is whether the operator's operation is scientific and standardized, and the other is reasonable daily maintenance. Here we mainly talk about the regular maintenance of line forming equipment. Its main function is to avoid accelerating the aging of the machine. The so-called daily maintenance of wire forming equipment refers to things that must be done almost every day, but the content is relatively simple and easy, mainly including the cleaning, lubrication, inspection and tightening of the machine, etc.The second is the regular maintenance of line forming equipment: regular maintenance is slightly different from daily maintenance. The time interval of regular maintenance is relatively long and does not need to be carried out every day. It is usually after the working hours specified for machine maintenance are reached or exceeded, but the content of maintenance There are relatively many and complex ones. Its maintenance content mainly includes the following contents: 1. Check and adjust the working conditions of transmission, clutch, engine, transmission mechanism, braking mechanism, steering and working devices, servo system and electrical system; 2. Detect and eliminate hidden faults, and balance the wear and tear of each component; 3. All relevant fasteners should be lubricated and cleaned regularly; 4. If it is not used for a long time, it should be deactivated and maintained, and cleaning and anti-corrosion work should be done.

3.What are the advantages of using a wire rotating forming machine over manual bending methods?

Our company has many years of wire rotating forming machine experience and expertise. Increased accuracy: Bending machines are designed to produce precise bends with minimal variation in angle and radius. This ensures that the finished product is of a higher quality than if it were bent manually. Increased speed: Bending machines can bend metal much faster than manual methods, allowing for faster production times. Increased safety: Bending machines reduce the risk of injury to operators, as they are designed to be operated from a safe distance. Reduced material waste: Bending machines are designed to use the minimum amount of material necessary to produce the desired shape, reducing material waste. Reduced labor costs: Bending machines require fewer operators than manual methods, reducing labor costs.

4.About the development history of wire rotating forming machine factory

Huide Machinery Manufacturing Co., Ltd. was established in 2008. It is an innovative and creative enterprise specializing in metal wire forming, integrating R&D, design, production, sales and service. In the past 15 years of development, the company has always adhered to customer-oriented Demand-oriented, with product quality as the foundation, technological innovation as the basis for development, and customer service as the basis for market expansion, we work tirelessly and continuously to advance, and are always committed to maximizing the interests of business owners, operators, and employees. Today, Huide's products are sold all over the world and are exported to more than 120 countries. It accounts for more than 60% of the domestic peer market and 75% of the world's share. Its overall strength and various economic indicators of its products have ranked among the best in the country for many years. It ranks among the best in the industry and is recognized as a leader in the same industry in China.

5.About wire rotating forming machine origin

The servo motors and electrical components are imported brands, and the machine frame is cut and manufactured by our factory.

6.About wire rotating forming machine overseas warehouse

we have agent In turkey

7.About wire rotating forming machine payment method

We accept T/T, Western Union L/C etc.

8.What is the maximum thickness of material that can be bent using a wire rotating forming machine?

We continuously upgrade our skills and knowledge to adapt to changing wire rotating forming machine market needs. The maximum thickness of material that can be bent using a bending machine depends on the type of machine and the material being bent. Generally, machines can bend materials up to 1/4 inch thick. However, some machines can bend materials up to 1 inch thick.

9.About wire rotating forming machine delivery date

If it is in stock, the delivery time is 3-4 working days. If it is not in stock, the delivery time is 10-15 days.

10.What materials can be bent using a wire rotating forming machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. bending machine can be used to bend a variety of materials, including metal, wood, plastic, and composite materials. Common metals that can be bent using a bending machine include aluminum, steel, copper, brass, and stainless steel.

11.Does the size of the wire rotating forming machine affect its capabilities?

Our products & services cover a wide range of areas and meet the needs of different fields. The size of the machine will not affect the performance of the machine. Instead, the diameter range of the wire, the material, and the requirements for processing the workpiece will determine the size of the machine. The larger the processing range, the larger the size of the machine will be, but the work efficiency will be the same. identical

12.What factors should be considered when choosing a wire rotating forming machine for a specific application?

We operate our wire rotating forming machine business with integrity and honesty. 1. The type of material to be bent: Different materials require different bending machines. 2. The size and shape of the material: The size and shape of the material will determine the type of bending machine needed. 3. The desired bend radius: The bend radius will determine the type of bending machine needed. 4. The desired bend angle: The bend angle will determine the type of bending machine needed. 5. The desired speed of the bending process: The speed of the bending process will determine the type of bending machine needed. 6. The desired accuracy of the bend: The accuracy of the bend will determine the type of bending machine needed. 7. The desired production rate: The production rate will determine the type of bending machine needed. 8. The available space: The available space will determine the type of bending machine needed. 9. The budget: The budget will determine the type of bending machine needed.