huide

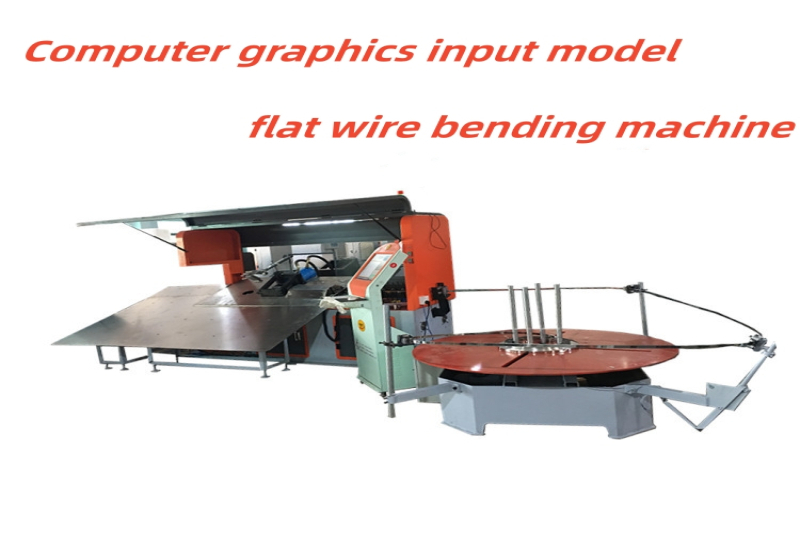

wire rod bending machine

| Place of Origin | China |

| Bending method | 1.Servo Bending 2.hydraulic Bending |

| Machine Type | wire rod bending machine |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump |

| Weight (KG) | 2178 |

| Key Selling Points | Competitive Price |

| run the country | Samoa |

| Warranty | 1 years |

| Applicable Industries | Posts and Guardrails |

| Certification | IS09001, 2015 |

| Raw Material | Carbon steel, SS |

| Material / Metal Processed | ALLOY |

| Product name | wire rod bending machine |

| Keyword | hook wire bending machine |

| Wire diameter | 19.29mm-12.35mm |

| Size | 3631*772*1225 |

| Wire type | Square, Round wire bending |

| Marketing Type | Ordinary Product |

| Payment terms | 30%T/T in advanced payment,the left payment should be paid after we finish our production.( we will take machine and packing photos for your checking ) We have our own forwarder. We can check the delivery information timely.(bending wire machine suppliers) |

| Packing | In standard export wooden case for wire bending Machine Delivery time:within 15 days after receiving your |

| Wire forming machine is suitable for various metals | (such as steel, iron, stainless steel, aluminum wire, etc.) |

| Features | Twisting head is designed in copper tube transport, more stable and stronger than bearing transfer Technical parameters |

Three groups of strong feeding-wire roller subassemblies powered with a servomotor ensure accurate wire feeding and excellent straightening.

HUIDE( Fengsheng )Machinery Integrity management Fine workmanship professional team

Graphic input 2d wire forming machine diameter range 2- 10mm

automatic wire bending machine supplier-OEM/ODM service is available. Low MOQ, we can accept low MOQ as 3 sets, or even less quantity for every single item in big production order. We have full experience in exporting and project management, to secure your order 100%.

wire rod bending machine services FAQs Guide Are you looking for a quick review guide about wire rod bending machineservices? An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding wire rod bending machine services. Let’s continue!

2.can we do OEM and ODM?

3.About wire rod bending machine delivery date

4.How does a CNC wire rod bending machine differ from a manual wire rod bending machine?

5.About wire rod bending machine origin

6.What are the different types of wire rod bending machines?

7.Is it possible to automate the bending process with a wire rod bending machine?

8.Can a wire rod bending machine create different types of bends?

9.How long does it take to set up a wire rod bending machine for a new project?

10.About wire rod bending machine technology

1.Are there any environmental concerns when using a wire rod bending machine?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. The time it takes to set up a bending machine for a new project will depend on the complexity of the project and the type of machine being used. Generally, it can take anywhere from a few hours to a few days to set up a bending machine for a new project. The working environment temperature of the machine cannot be too low or too high. The maximum temperature should not exceed 45 degrees. High temperature will cause the servo motor to alarm.

2.can we do OEM and ODM?

Can changing on design , color ,: acceptable(welcome) develop on artwork and sketch : acceptable

3.About wire rod bending machine delivery date

If it is in stock, the delivery time is 3-4 working days. If it is not in stock, the delivery time is 10-15 days.

4.How does a CNC wire rod bending machine differ from a manual wire rod bending machine?

Our products & services cover a wide range of areas and meet the needs of different fields. A CNC bending machine is a computer-controlled machine that uses a programmable logic controller (PLC) to control the bending process. It is capable of producing complex bends with high accuracy and repeatability. It is also able to produce multiple bends in a single operation. A manual bending machine is operated manually and requires the operator to manually adjust the bending angle and pressure. It is not as accurate or repeatable as a CNC bending machine and is limited to producing simple bends. It can be completed from modulation, wire feeding, bending, cutting, all on one machine at one time. However, with a manual bending machine, you need to straighten and cut the wire on the straightening and cutting machine first, and then manually put it on the bending machine. bending. Moreover, the working efficiency of intelligent bending machines is much higher than that of manual bending machines, saving labor costs.

5.About wire rod bending machine origin

The servo motors and electrical components are imported brands, and the machine frame is cut and manufactured by our factory.

6.What are the different types of wire rod bending machines?

Our company has many years of wire rod bending machine experience and expertise. 1. Hydraulic Press Brake: This type of bending machine uses a hydraulic cylinder to apply pressure to a workpiece in order to bend it. 2. Mechanical Press Brake: This type of bending machine uses a mechanical ram to apply pressure to a workpiece in order to bend it. 3. Roll Bending Machine: This type of bending machine uses a set of three or more rolls to bend a workpiece. 4. Sheet Metal Bending Machine: This type of bending machine is used to bend sheet metal into various shapes. 5. Tube Bending Machine: This type of bending machine is used to bend tubes into various shapes. 6. CNC Bending Machine: This type of bending machine is computer-controlled and can be programmed to bend a workpiece into a specific shape.

7.Is it possible to automate the bending process with a wire rod bending machine?

Our wire rod bending machine products undergo strict quality control to ensure customer satisfaction. A wire bending machine is a device that can bend metal wires at specified angles and shapes. It is widely used in electronics, communications, automobiles, home appliances and other industries to produce various wire components and electrical wiring harnesses. The emergence of wire bending machines has greatly improved production efficiency, reduced manual labor intensity, and ensured the stability of product quality.

8.Can a wire rod bending machine create different types of bends?

We focus on innovation and continuous improvement to maintain a competitive advantage. Our system can store 10,000 graphics, and you can choose between manual programming and graphics input systems.

9.How long does it take to set up a wire rod bending machine for a new project?

We continuously upgrade our skills and knowledge to adapt to changing wire rod bending machine market needs. If special workpiece requirements require a redesign of the machine, it will take approximately 45-60 days from designing the machine drawings to assembling the complete machine. If it is a conventional machine, it usually takes 15-20 days to assemble the machine.

10.About wire rod bending machine technology

We have 5 designers, all of whom have been engaged in the machine design industry for 20 years. Our graphics input system is the first in the Chinese market and is also our patented product.