huide

wire iron rode bending machine

| Place of Origin | China |

| Condition | New |

| Machine Type | wire iron rode bending machine |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump |

| Weight (KG) | 2873 |

| Key Selling Points | Competitive Price |

| Warranty | 1 years |

| Applicable Industries | auto parts |

| Raw Material | Carbon steel, SS |

| Material / Metal Processed | ALLOY |

| Product name | wire iron rode bending machine |

| Keyword | bending wire cloth machine |

| Wire diameter | 20.47mm-18.26mm |

| Wire type | Square, Round wire bending |

| Marketing Type | Ordinary Product |

| Payment terms | 30%T/T in advanced payment,the left payment should be paid after we finish our production.( we will take machine and packing photos for your checking ) We have our own forwarder. We can check the delivery information timely. |

| Packing | In standard export wooden case for wire bending Machine Delivery time:within 15 days after receiving your |

| Wire forming machine is suitable for various metals | (such as steel, iron, stainless steel, aluminum wire, etc.) |

| Features | Twisting head is designed in copper tube transport, more stable and stronger than bearing transfer Technical parameters(china wire bending machine manufacturer) |

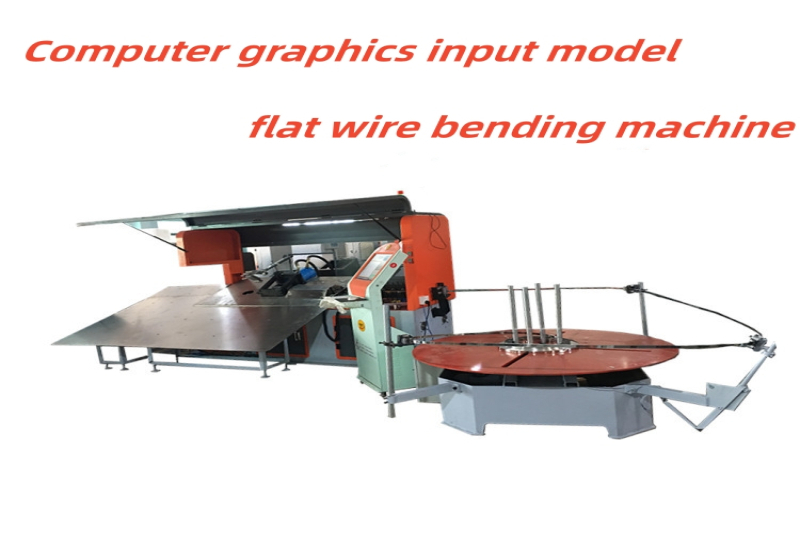

Graphic input rotary head 3D wire forming machine composition and structure

wire iron rode bending machineApplication Field

HUIDE( Fengsheng )Machinery Integrity management Fine workmanship professional team

3d cnc wire bending machine manufacturers-OEM/ODM service is available. Low MOQ, we can accept low MOQ as 8 sets, or even less quantity for every single item in big production order. We have full experience in exporting and project management, to secure your order 100%.

wire iron rode bending machine services FAQs Guide Are you looking for a quick review guide about wire iron rode bending machineservices? An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding wire iron rode bending machine services. Let’s continue!

2.About wire iron rode bending machine payment method

3.How can the accuracy of a wire iron rode bending machine be improved?

4.Is it possible to automate the bending process with a wire iron rode bending machine?

5.can we do OEM and ODM?

6.What is the maximum thickness of material that can be bent using a wire iron rode bending machine?

7.What are the main components of a wire iron rode bending machine?

8.About wire iron rode bending machine patent

9.About wire iron rode bending machine customization services

10.Does the size of the wire iron rode bending machine affect its capabilities?

11.How does a CNC wire iron rode bending machine differ from a manual wire iron rode bending machine?

12.About wire iron rode bending machine production capacity

13.What are the different types of wire iron rode bending machines?

14.What materials can be bent using a wire iron rode bending machine?

1.What are the most common applications for a wire iron rode bending machine?

We focus on innovation and continuous improvement to maintain a competitive advantage. 1.Auto Industry area 2.Metal wire industry 3.Display table and cargo shelf 4.Furniture and Kitchen 5.Hardware industry 6.Mattress, Sofa spring area 7.Architecture area 8.Hardware Artcraft

2.About wire iron rode bending machine payment method

We accept T/T, Western Union L/C etc.

3.How can the accuracy of a wire iron rode bending machine be improved?

As one of the wire iron rode bending machine market leaders, we are known for innovation and reliability. 1. Regularly inspect and maintain the machine to ensure that all components are in good working order. 2. Use high-quality materials for the machine components. 3. Use a high-precision measuring device to ensure accuracy. 4. Use a high-precision cutting tool to ensure accuracy. 5. Use a high-precision bending tool to ensure accuracy. 6. Use a high-precision clamping system to ensure accuracy. 7. Use a high-precision control system to ensure accuracy. 8. Use a high-precision feedback system to ensure accuracy. 9. Use a high-precision lubrication system to ensure accuracy. 10. Use a high-precision cooling system to ensure accuracy.

4.Is it possible to automate the bending process with a wire iron rode bending machine?

Our wire iron rode bending machine products undergo strict quality control to ensure customer satisfaction. A wire bending machine is a device that can bend metal wires at specified angles and shapes. It is widely used in electronics, communications, automobiles, home appliances and other industries to produce various wire components and electrical wiring harnesses. The emergence of wire bending machines has greatly improved production efficiency, reduced manual labor intensity, and ensured the stability of product quality.

5.can we do OEM and ODM?

Can changing on design , color ,: acceptable(welcome) develop on artwork and sketch : acceptable

6.What is the maximum thickness of material that can be bent using a wire iron rode bending machine?

We continuously upgrade our skills and knowledge to adapt to changing wire iron rode bending machine market needs. The maximum thickness of material that can be bent using a bending machine depends on the type of machine and the material being bent. Generally, machines can bend materials up to 1/4 inch thick. However, some machines can bend materials up to 1 inch thick.

7.What are the main components of a wire iron rode bending machine?

wire iron rode bending machine is not a product only, but also can help you comes to money-making. Distribution line assembly, straightening mechanism, bending line assembly, hydraulic system, electrical control part. 1, hydraulic system (control the outer mold lift and cutter); 2, wire assembly (to complete the delivery of materials); 3, straightening institutions (straight wire); 4, bending line assembly (product molding).

8.About wire iron rode bending machine patent

Our machines have more than 20 invention patents

9.About wire iron rode bending machine customization services

We can design customized machines according to customers' special drawing requirements, and also accept OEM services.

10.Does the size of the wire iron rode bending machine affect its capabilities?

Our products & services cover a wide range of areas and meet the needs of different fields. The size of the machine will not affect the performance of the machine. Instead, the diameter range of the wire, the material, and the requirements for processing the workpiece will determine the size of the machine. The larger the processing range, the larger the size of the machine will be, but the work efficiency will be the same. identical

11.How does a CNC wire iron rode bending machine differ from a manual wire iron rode bending machine?

Our products & services cover a wide range of areas and meet the needs of different fields. A CNC bending machine is a computer-controlled machine that uses a programmable logic controller (PLC) to control the bending process. It is capable of producing complex bends with high accuracy and repeatability. It is also able to produce multiple bends in a single operation. A manual bending machine is operated manually and requires the operator to manually adjust the bending angle and pressure. It is not as accurate or repeatable as a CNC bending machine and is limited to producing simple bends. It can be completed from modulation, wire feeding, bending, cutting, all on one machine at one time. However, with a manual bending machine, you need to straighten and cut the wire on the straightening and cutting machine first, and then manually put it on the bending machine. bending. Moreover, the working efficiency of intelligent bending machines is much higher than that of manual bending machines, saving labor costs.

12.About wire iron rode bending machine production capacity

50sets/month

13.What are the different types of wire iron rode bending machines?

Our company has many years of wire iron rode bending machine experience and expertise. 1. Hydraulic Press Brake: This type of bending machine uses a hydraulic cylinder to apply pressure to a workpiece in order to bend it. 2. Mechanical Press Brake: This type of bending machine uses a mechanical ram to apply pressure to a workpiece in order to bend it. 3. Roll Bending Machine: This type of bending machine uses a set of three or more rolls to bend a workpiece. 4. Sheet Metal Bending Machine: This type of bending machine is used to bend sheet metal into various shapes. 5. Tube Bending Machine: This type of bending machine is used to bend tubes into various shapes. 6. CNC Bending Machine: This type of bending machine is computer-controlled and can be programmed to bend a workpiece into a specific shape.

14.What materials can be bent using a wire iron rode bending machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. bending machine can be used to bend a variety of materials, including metal, wood, plastic, and composite materials. Common metals that can be bent using a bending machine include aluminum, steel, copper, brass, and stainless steel.