huide

wire forming machine supplier

| Place of Origin | China |

| Condition | New |

| Machine Type | wire forming machine supplier |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump |

| Weight (KG) | 2022 |

| Key Selling Points | Competitive Price |

| Warranty | 1 years |

| Applicable Industries | bathroom racks |

| Raw Material | Carbon steel, SS |

| Material / Metal Processed | ALLOY |

| Product name | wire forming machine supplier |

| Keyword | automatic 3d wire bending machine |

| Wire diameter | 11.14mm-9.84mm |

| Wire type | Square, Round wire bending |

| Marketing Type | Ordinary Product |

| Payment terms | 30%T/T in advanced payment,the left payment should be paid after we finish our production.( we will take machine and packing photos for your checking ) We have our own forwarder. We can check the delivery information timely. |

| Packing | In standard export wooden case for wire bending Machine Delivery time:within 15 days after receiving your |

| Wire forming machine is suitable for various metals | (such as steel, iron, stainless steel, aluminum wire, etc.) |

| Features | Twisting head is designed in copper tube transport, more stable and stronger than bearing transfer Technical parameters(china wire bending machine supplier) |

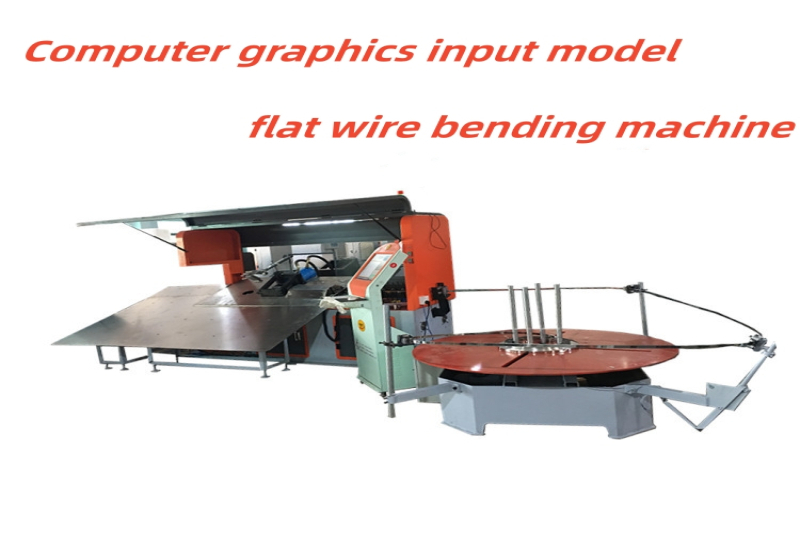

Graphic input rotary head 3D wire forming machine composition and structure

Our Market includes these Azerbaijan,Grenada,Qatar,Comoros,India,Singapore,Solomon Islands,Afghanistan

The package and shipping of Packing: wire forming machine supplier Standard export wooden box delivery timewithin 15 days after receiving your

china wire bending machine manufacturer-OEM/ODM service is available. Low MOQ, we can accept low MOQ as 1 sets, or even less quantity for every single item in big production order. We have full experience in exporting and project management, to secure your order 100%.

wire forming machine supplier services FAQs Guide Are you looking for a quick review guide about wire forming machine supplierservices? An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding wire forming machine supplier services. Let’s continue!

2.About wire forming machine supplier MOQ

3.About wire forming machine supplier patent

4.What are the advantages of using a wire forming machine supplier over manual bending methods?

5.What is the difference between a press brake and a wire forming machine supplier?

6.How can the accuracy of a wire forming machine supplier be improved?

7.About wire forming machine supplier quality system

8.What materials can be bent using a wire forming machine supplier?

9.About wire forming machine supplier warranty

10.What are the different types of wire forming machine suppliers?

11.About wire forming machine supplier inventory

1.About wire forming machine supplier technology

We have 5 designers, all of whom have been engaged in the machine design industry for 20 years. Our graphics input system is the first in the Chinese market and is also our patented product.

2.About wire forming machine supplier MOQ

1set can be acceptable for trail order.

3.About wire forming machine supplier patent

Our machines have more than 20 invention patents

4.What are the advantages of using a wire forming machine supplier over manual bending methods?

Our company has many years of wire forming machine supplier experience and expertise. Increased accuracy: Bending machines are designed to produce precise bends with minimal variation in angle and radius. This ensures that the finished product is of a higher quality than if it were bent manually. Increased speed: Bending machines can bend metal much faster than manual methods, allowing for faster production times. Increased safety: Bending machines reduce the risk of injury to operators, as they are designed to be operated from a safe distance. Reduced material waste: Bending machines are designed to use the minimum amount of material necessary to produce the desired shape, reducing material waste. Reduced labor costs: Bending machines require fewer operators than manual methods, reducing labor costs.

5.What is the difference between a press brake and a wire forming machine supplier?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. Wire forming machines are used to produce wire forming products. It means that a steel wire goes in and is made into a flat or three-dimensional linear product through the work of a bending head, or the wire is processed by a corner bender and folded into various flat or three-dimensional steel wire parts of various shapes. A bending machine is a machine that can bend thin plates. Its structure mainly includes a bracket, a workbench and a clamping plate. The workbench is placed on the bracket. The workbench is composed of a base and a pressure plate. The base is connected to the clamping plate through hinges. Connected, the base is composed of a seat shell, a coil and a cover plate. The coil is placed in the depression of the seat shell, and the top of the depression is covered with a cover plate. When in use, the coil is energized by the wire, and the energized force exerts a gravitational force on the pressure plate, thereby clamping the thin plate between the pressure plate and the base.

6.How can the accuracy of a wire forming machine supplier be improved?

As one of the wire forming machine supplier market leaders, we are known for innovation and reliability. 1. Regularly inspect and maintain the machine to ensure that all components are in good working order. 2. Use high-quality materials for the machine components. 3. Use a high-precision measuring device to ensure accuracy. 4. Use a high-precision cutting tool to ensure accuracy. 5. Use a high-precision bending tool to ensure accuracy. 6. Use a high-precision clamping system to ensure accuracy. 7. Use a high-precision control system to ensure accuracy. 8. Use a high-precision feedback system to ensure accuracy. 9. Use a high-precision lubrication system to ensure accuracy. 10. Use a high-precision cooling system to ensure accuracy.

7.About wire forming machine supplier quality system

Our machines have more than 20 invention patents and have CE, IAF, ISOACM and other certifications, and belong to the high-tech industry.

8.What materials can be bent using a wire forming machine supplier?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. bending machine can be used to bend a variety of materials, including metal, wood, plastic, and composite materials. Common metals that can be bent using a bending machine include aluminum, steel, copper, brass, and stainless steel.

9.About wire forming machine supplier warranty

Starting from the receipt of the bill of lading, if it is not caused by human factors, the whole machine is guaranteed for one year. If the machine parts are damaged due to the reason, we will provide the machine parts at the cost price, but the customer needs to bear the freight.

10.What are the different types of wire forming machine suppliers?

Our company has many years of wire forming machine supplier experience and expertise. 1. Hydraulic Press Brake: This type of bending machine uses a hydraulic cylinder to apply pressure to a workpiece in order to bend it. 2. Mechanical Press Brake: This type of bending machine uses a mechanical ram to apply pressure to a workpiece in order to bend it. 3. Roll Bending Machine: This type of bending machine uses a set of three or more rolls to bend a workpiece. 4. Sheet Metal Bending Machine: This type of bending machine is used to bend sheet metal into various shapes. 5. Tube Bending Machine: This type of bending machine is used to bend tubes into various shapes. 6. CNC Bending Machine: This type of bending machine is computer-controlled and can be programmed to bend a workpiece into a specific shape.

11.About wire forming machine supplier inventory

usually we have 10 sets stock machine in factory .