huide

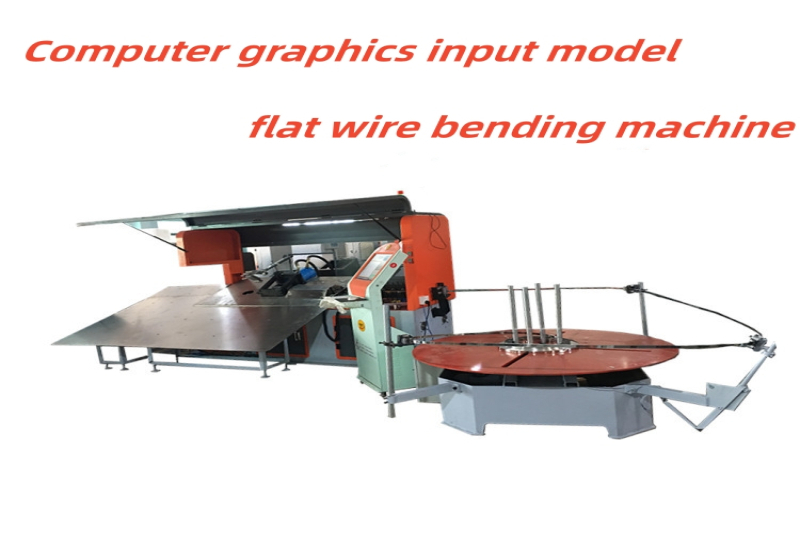

wire forming machine

| Place of Origin | China |

| Condition | New |

| Machine Type | wire forming machine |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump |

| Weight (KG) | 2564 |

| Key Selling Points | Competitive Price |

| Warranty | 1 years |

| Applicable Industries | crafts |

| Raw Material | Carbon steel, SS |

| Material / Metal Processed | ALLOY |

| Product name | wire forming machine |

| Keyword | copper wire bending machine |

| Wire diameter | 10.01mm-13.07mm |

| Wire type | Square, Round wire bending |

| Marketing Type | Ordinary Product |

| Payment terms | 30%T/T in advanced payment,the left payment should be paid after we finish our production.( we will take machine and packing photos for your checking ) We have our own forwarder. We can check the delivery information timely. |

| Packing | In standard export wooden case for wire bending Machine Delivery time:within 15 days after receiving your |

| Wire forming machine is suitable for various metals | (such as steel, iron, stainless steel, aluminum wire, etc.) |

| Features | Twisting head is designed in copper tube transport, more stable and stronger than bearing transfer Technical parameters(china 3d cnc wire bending machine suppliers) |

HUIDE( Fengsheng )Machinery Integrity management Fine workmanship professional team

Graphic input 2d wire forming machine diameter range 2- 10mm

Movable bearings in the inner and outer molds enable trace,

china 3d cnc wire bending machine supplier-OEM/ODM service is available. Low MOQ, we can accept low MOQ as 5 sets, or even less quantity for every single item in big production order. We have full experience in exporting and project management, to secure your order 100%.

wire forming machine services FAQs Guide Are you looking for a quick review guide about wire forming machineservices? An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding wire forming machine services. Let’s continue!

2.About wire forming machine MOQ

3.What materials can be bent using a wire forming machine?

4.What is the difference between a press brake and a wire forming machine?

5.What is the maximum thickness of material that can be bent using a wire forming machine?

6.About wire forming machine R&D capabilities

7.About wire forming machine technology

8.How long does it take to set up a wire forming machine for a new project?

9.What are the different bending methods used in a wire forming machine?

10.What are the main components of a wire forming machine?

11.About wire forming machine delivery date

12.About wire forming machine patent

1.How does a CNC wire forming machine differ from a manual wire forming machine?

Our products & services cover a wide range of areas and meet the needs of different fields. A CNC bending machine is a computer-controlled machine that uses a programmable logic controller (PLC) to control the bending process. It is capable of producing complex bends with high accuracy and repeatability. It is also able to produce multiple bends in a single operation. A manual bending machine is operated manually and requires the operator to manually adjust the bending angle and pressure. It is not as accurate or repeatable as a CNC bending machine and is limited to producing simple bends. It can be completed from modulation, wire feeding, bending, cutting, all on one machine at one time. However, with a manual bending machine, you need to straighten and cut the wire on the straightening and cutting machine first, and then manually put it on the bending machine. bending. Moreover, the working efficiency of intelligent bending machines is much higher than that of manual bending machines, saving labor costs.

2.About wire forming machine MOQ

1set can be acceptable for trail order.

3.What materials can be bent using a wire forming machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. bending machine can be used to bend a variety of materials, including metal, wood, plastic, and composite materials. Common metals that can be bent using a bending machine include aluminum, steel, copper, brass, and stainless steel.

4.What is the difference between a press brake and a wire forming machine?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. Wire forming machines are used to produce wire forming products. It means that a steel wire goes in and is made into a flat or three-dimensional linear product through the work of a bending head, or the wire is processed by a corner bender and folded into various flat or three-dimensional steel wire parts of various shapes. A bending machine is a machine that can bend thin plates. Its structure mainly includes a bracket, a workbench and a clamping plate. The workbench is placed on the bracket. The workbench is composed of a base and a pressure plate. The base is connected to the clamping plate through hinges. Connected, the base is composed of a seat shell, a coil and a cover plate. The coil is placed in the depression of the seat shell, and the top of the depression is covered with a cover plate. When in use, the coil is energized by the wire, and the energized force exerts a gravitational force on the pressure plate, thereby clamping the thin plate between the pressure plate and the base.

5.What is the maximum thickness of material that can be bent using a wire forming machine?

We continuously upgrade our skills and knowledge to adapt to changing wire forming machine market needs. The maximum thickness of material that can be bent using a bending machine depends on the type of machine and the material being bent. Generally, machines can bend materials up to 1/4 inch thick. However, some machines can bend materials up to 1 inch thick.

6.About wire forming machine R&D capabilities

With large-scale precision machining centers, CNC lathes and other processing equipment, it is the first enterprise in Hebei Province to realize the manufacturing of high-precision wire 3D printing equipment, and has an annual production capacity of 300 wire forming machines. Wire forming machines are mostly used in car seat frame and muffler hook forming, motorcycle and bicycle rear tail rack and basket forming, kitchen and bathroom racks, refrigerator dishwasher hanging baskets, supermarket trolleys, shelf hooks, wrought iron molding, and lighting fixtures. and other fields, with a wide range of applications. With the development of the industry, the requirements for equipment automation are getting higher and higher. Xingtai Zhongde Machinery products are sold throughout the country and more than 60 countries and regions in Europe, America, Southeast Asia, the Middle East, and North Africa. In the past three years, the domestic market share has continued to increase, ranking first in the sales of wire forming equipment in Gyangdong Province.

7.About wire forming machine technology

We have 5 designers, all of whom have been engaged in the machine design industry for 20 years. Our graphics input system is the first in the Chinese market and is also our patented product.

8.How long does it take to set up a wire forming machine for a new project?

We continuously upgrade our skills and knowledge to adapt to changing wire forming machine market needs. If special workpiece requirements require a redesign of the machine, it will take approximately 45-60 days from designing the machine drawings to assembling the complete machine. If it is a conventional machine, it usually takes 15-20 days to assemble the machine.

9.What are the different bending methods used in a wire forming machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. (1) Free bending The free bending method is the most commonly used method. Free bending uses the two edges at the opening of the die and the edge at the top of the punch to perform bending. The bending angle is determined by the depth of the punch entering the die. The bending force required for free bending is smaller, the stress on the mold is gentler, and the service life of the mold can be extended. The disadvantage is that the thickness of the sheet, the inconsistency of the mechanical properties, and the rolling direction of the steel plate will cause changes in the bending angle. (2) Correction of bending Corrective bending is when the punch presses the rounded corners and straight edges of the workpiece. During the downward movement of the punch, the angle of the blank will be smaller than the angle of the concave mold, resulting in negative rebound; at the end of the stroke, the punch and concave mold will correct the blank so that its rounded corners, straight edges, and bending radii are all close to the punch. . It can be seen that corrective bending can effectively overcome the rebound effect, thereby achieving high bending accuracy. (3) Three-point bending To process this part with a CNC press, you only need to program it and clamp and position it once to complete the entire processing. The programming time is two to three hours at most, the processing time is only a few minutes, and the processing accuracy is high. The hydraulic pad pressure is evenly distributed over the entire bending length, so that the bending force of the punch is evenly distributed over the entire bending length. Each punch is elastically supported, so it can automatically adapt to the bending straightness of the die and ensure constant pressure distribution, thus improving the accuracy of the bending angle and the straightness of the bending edge. The bending angle error of the three-point bending method is ±15 degrees, which is equivalent to the accuracy of corrected bending. The bending thickness can reach 20mm. When the plate thickness exceeds 3mm, the three-point bending method is the only way to obtain the bend. This is because, in addition, if you want to obtain the same bending accuracy, you can only use correction bending, but the bending force will exceed the pressure limit that the mold can withstand.

10.What are the main components of a wire forming machine?

wire forming machine is not a product only, but also can help you comes to money-making. Distribution line assembly, straightening mechanism, bending line assembly, hydraulic system, electrical control part. 1, hydraulic system (control the outer mold lift and cutter); 2, wire assembly (to complete the delivery of materials); 3, straightening institutions (straight wire); 4, bending line assembly (product molding).

11.About wire forming machine delivery date

If it is in stock, the delivery time is 3-4 working days. If it is not in stock, the delivery time is 10-15 days.

12.About wire forming machine patent

Our machines have more than 20 invention patents