huide

vertical thread rolling machine factory

Thanks to perfect management, advanced technology, reliable quality and first-class service, international CE certification, IS09001, 2015 quality system certification and coat rack appearance patent certification.

| Product name | vertical thread rolling machine factory |

| Keyword | thread rolling machine ludhiana,thread rolling machine for sale in usa,rebar straight thread rolling machine,hydraulic thread rolling machine manufacturer in ludhiana,thread thread rolling machine,advance thread rolling machine supplier,acme thread rolling machine |

| Place of Origin | China |

| Production Capacity | 284~400/Per Min |

| Power | 2.2~6kw |

| Thread Dia(mm) | 2.0~4.0 |

| Thread Length(mm) | 7~50 |

| Feature | pipe nipple threading machine in its rolling pressure range of cold, the workpiece for thread, ruled, twill and other treatment; straight, helical and oblique spline gear rolling; straightening, reducing diameter, rolling and various forming rolling. |

| Dimensions | 1657mm*1926mm*1558mm, (Contact us for specific information to confirm) |

| Applicable Industries | Automotive Manufacturing, etc. |

| Color | pink or customized |

| Weight | 2841kg |

| Product Description | The machine has a safe and reliable electro-hydraulic execution and control system. Each work cycle can be selected in manual, semi-automatic and automatic ways. |

| terms of packing | enerally, we pack our goods in plywood cases. |

| terms of paymen | T/T 30% as deposit, and 70% balance against BL copy |

| Life span | 18 years (Contact us for specific information to confirm) |

| After-sale service | 12 months warrantly, man-made destory will be exception. |

| vertical thread rolling machine factory Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 2566x2405x1920mm(Contact us for specific information to confirm) |

| OEM/ODM | Customization Service Provided |

| Sales country | All over the world for example:Senegal,Austria,Cape Verde,Samoa,Palau,Ukraine,Chile |

| MOQ | 9pcs(Contact us for specific information to confirm) |

| Delivery time | 15-20 days for OEM, 5-7days for ready goods. |

vertical thread rolling machine factory

huide-machinery.as one of the most professional vertical thread rolling machine factory manufacturer has the advantages at:

We are the leader thread rolling machine supplier in China, also we have customers worldwide, such as America, Argentina, Brazil, Belarus, Bangladesh, Senegal,Austria,Cape Verde,Samoa,Palau,Ukraine,Chile, and Italy.We are factory specializing in the manufacture and export of thread rolling machine for more than 20 years, all of the production we sale are at a very best price and high quality.

We take care of our product quality, any defect of the goods, we will take responsibility. You are risk-free.And we believe that the good quality products will can give us survival, so, we always offer the top quality products to our customers, to keep them have the competitiveness in there market.

vertical thread rolling machine factory services FAQs Guide

Are you looking for a quick review guide about vertical thread rolling machine factoryservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding vertical thread rolling machine factory services.

Let’s continue!

2. If the machine get damaged, what can I do ?

3.Can a vertical thread rolling machine factory Create Internal Threads?

4.Can a vertical thread rolling machine factory handle both internal and external threads?

5.Can a vertical thread rolling machine factory be Automated?

6.What Quality Control Measures are Used in vertical thread rolling machine factory Production?

7.Can a vertical thread rolling machine factory Create Threads with Different Tolerances?

8.What Types of Materials can be Used with a vertical thread rolling machine factory?

9.Can a vertical thread rolling machine factory Create Threads on Hard Materials?

10.What does your factory produce ?

11.What is the difference between thread rolling and thread cutting?

12.What are the Limitations of a vertical thread rolling machine factory?

13.What are the Main Components of a vertical thread rolling machine factory?

14.What safety precautions should be taken when operating a vertical thread rolling machine factory?

1.How Does the Thread Rolling Process Work?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

The thread rolling process is a cold forming process used to create external threads on a workpiece. It involves pressing a hardened steel die onto the surface of the workpiece, causing the material to flow and form the desired thread shape.

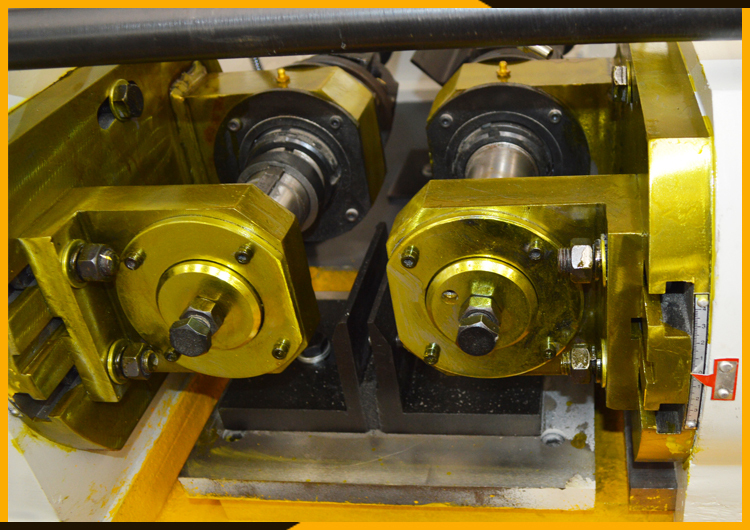

The process begins with a blank workpiece, typically a cylindrical rod or bar, which is fed into the thread rolling machine. The machine consists of two dies, an upper and a lower die, which are mounted on parallel spindles and rotate in opposite directions.

The upper die is stationary, while the lower die is adjustable and can be moved up and down to accommodate different thread sizes. The dies are also equipped with thread profiles that correspond to the desired thread shape.

As the workpiece is fed between the two dies, it is gripped and held in place by a set of rollers. The rollers apply pressure to the workpiece, forcing it to deform and flow into the thread profile of the dies.

The dies then rotate, causing the material to be displaced and formed into the desired thread shape. The pressure and rotation of the dies continue until the thread is fully formed.

Once the thread is formed, the dies retract, and the workpiece is released. The thread is then checked for accuracy using gauges and other measuring tools.

The thread rolling process is highly efficient and can produce threads at a much faster rate than traditional cutting methods. It also results in a stronger and more precise thread, making it a preferred method for creating high-quality threads in mass production.

2. If the machine get damaged, what can I do ?

In the guarantee time (15 months) , we will send the spare parts to you for free and provide the technical consultant for anytime. If more terrible, we can send our engineers to your factory. We will provide same good after-sale service as the pre-sale service. For any of your questions, we will reply within 12 hours.

3.Can a vertical thread rolling machine factory Create Internal Threads?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

Yes, a thread rolling machine can create internal threads. This process is known as internal thread rolling and it involves using a set of dies to form the threads on the inside of a cylindrical workpiece. This method is commonly used for creating threads on nuts, bolts, and other fasteners. Internal thread rolling is a faster and more efficient process compared to traditional methods such as tapping or cutting, and it also produces stronger and more precise threads.

4.Can a vertical thread rolling machine factory handle both internal and external threads?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously.

Yes, some thread rolling machines are designed to handle both internal and external threads. These machines have different sets of dies and adjustments to accommodate the different types of threads. However, some machines may only be able to handle either internal or external threads, so it is important to check the specifications of the specific machine.

5.Can a vertical thread rolling machine factory be Automated?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, a thread rolling machine can be automated. Automation can be achieved through the use of computer numerical control (CNC) technology, which allows for precise and repeatable control of the machine's movements and operations. This can greatly increase the efficiency and productivity of the thread rolling process, as well as reduce the potential for human error. Additionally, some thread rolling machines may also have built-in automation features such as automatic thread length measurement and adjustment, automatic lubrication systems, and automatic tool change capabilities.

6.What Quality Control Measures are Used in vertical thread rolling machine factory Production?

1. Material Inspection: The first step in quality control is to inspect the raw materials used in the production of thread rolling machines. This includes checking the quality and specifications of the steel, bearings, gears, and other components.

2. Machine Calibration: Before starting the production process, the thread rolling machine is calibrated to ensure that it is functioning properly and producing accurate threads.

3. In-process Inspection: During the production process, regular inspections are carried out to check the dimensions, surface finish, and other critical parameters of the thread rolling machine.

4. Statistical Process Control (SPC): SPC is a method used to monitor and control the production process by collecting and analyzing data. This helps to identify any variations or defects in the production process and take corrective actions.

5. Final Inspection: Once the thread rolling machine is completed, a final inspection is carried out to ensure that it meets all the required specifications and standards.

6. Performance Testing: The thread rolling machine is tested for its performance by running it with different types of materials and thread sizes to ensure that it can produce accurate and consistent threads.

7. Quality Management System: Most manufacturers have a quality management system in place to ensure that all the processes and procedures are followed correctly and any issues are addressed promptly.

7.Can a vertical thread rolling machine factory Create Threads with Different Tolerances?

Yes, a thread rolling machine can create threads with different tolerances. The machine can be adjusted to produce threads with different pitch, diameter, and depth, which ultimately affects the tolerance of the thread. The operator can also adjust the pressure and speed of the machine to achieve the desired tolerance. However, it is important to note that the accuracy and consistency of the thread rolling machine play a crucial role in achieving the desired tolerance. Regular maintenance and calibration of the machine are necessary to ensure consistent and accurate thread production.

8.What Types of Materials can be Used with a vertical thread rolling machine factory?

We continue to invest in research and development and continue to launch innovative products.

1. Metal: Thread rolling machines are primarily used for rolling threads on metal materials such as steel, aluminum, brass, and copper. These materials are commonly used in industries such as automotive, aerospace, and construction.

2. Plastic: Some thread rolling machines are also capable of rolling threads on plastic materials such as nylon, PVC, and acrylic. These materials are commonly used in industries such as electronics, medical, and consumer goods.

3. Wood: Thread rolling machines can also be used to create threads on wooden materials such as hardwood and softwood. These threads are commonly used in furniture making and woodworking industries.

4. Composite materials: Thread rolling machines can also be used to roll threads on composite materials such as carbon fiber, fiberglass, and Kevlar. These materials are commonly used in industries such as aerospace, marine, and sports equipment.

5. Rubber: Some thread rolling machines are also capable of rolling threads on rubber materials such as silicone, neoprene, and EPDM. These materials are commonly used in industries such as automotive, construction, and medical.

6. Ceramic: Thread rolling machines can also be used to create threads on ceramic materials such as porcelain, clay, and glass. These materials are commonly used in industries such as pottery, construction, and electronics.

7. Other materials: Depending on the type and capabilities of the thread rolling machine, it may also be able to roll threads on other materials such as leather, paper, and fabric. These materials are commonly used in industries such as fashion, packaging, and upholstery.

9.Can a vertical thread rolling machine factory Create Threads on Hard Materials?

Yes, a thread rolling machine can create threads on hard materials. Thread rolling is a cold forming process that uses pressure to deform the material and create threads. This process is suitable for both soft and hard materials, including steel, stainless steel, titanium, and other alloys. The pressure applied by the thread rolling machine can be adjusted to accommodate the hardness of the material, ensuring that the threads are formed without damaging the material. Additionally, thread rolling can produce stronger and more precise threads compared to other methods such as cutting or tapping, making it a preferred method for creating threads on hard materials.

10.What does your factory produce ?

We produce and export all kinds of Reinforced Bar Thread Rolling Machine with butt welding. We also can design and develop automatic wire ring making machines with butt welding according to your requirements.

11.What is the difference between thread rolling and thread cutting?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

Thread rolling and thread cutting are two different methods used to create threads on a workpiece. The main difference between them lies in the way the threads are formed.

Thread rolling is a cold forming process in which a hardened steel die is pressed against the surface of a rotating workpiece. The pressure from the die creates the threads on the workpiece by displacing the material. This process is typically used for creating external threads on cylindrical parts, such as bolts, screws, and studs. It is a highly efficient and precise method that produces strong and accurate threads.

On the other hand, thread cutting is a machining process in which a cutting tool is used to remove material from the workpiece to create threads. The cutting tool is usually a tap or a die, and it is rotated or moved along the workpiece to cut the threads. This process is commonly used for creating internal threads on holes or external threads on shafts. It is a slower process compared to thread rolling, but it allows for more flexibility in terms of thread size and shape.

In summary, thread rolling is a cold forming process that uses pressure to create threads, while thread cutting is a machining process that uses cutting tools to remove material and create threads. Both methods have their advantages and are used in different applications depending on the requirements.

12.What are the Limitations of a vertical thread rolling machine factory?

Our vertical thread rolling machine factory products undergo strict quality control to ensure customer satisfaction.

1. Limited to cylindrical parts: Thread rolling machines are only suitable for producing threads on cylindrical parts. They cannot be used for producing threads on non-cylindrical or irregularly shaped parts.

2. Limited thread size range: Thread rolling machines have a limited range of thread sizes that they can produce. This is determined by the size of the thread rolling dies used in the machine.

3. Limited thread types: Thread rolling machines are designed to produce only straight threads. They cannot produce tapered or helical threads.

4. High initial cost: Thread rolling machines are expensive to purchase and set up, making them less accessible for small businesses or hobbyists.

5. Limited material compatibility: Thread rolling machines are not suitable for all types of materials. They work best with softer materials such as aluminum, brass, and low carbon steel.

13.What are the Main Components of a vertical thread rolling machine factory?

I have a comprehensive after -sales service system, which can pay attention to market trends in time and adjust our strategy in a timely manner.

1. Bed: The bed is the main structural component of a thread rolling machine. It provides a stable base for all other components and supports the weight of the machine.

2. Headstock: The headstock is the part of the machine that holds the workpiece and rotates it during the thread rolling process. It also houses the drive mechanism for the workpiece rotation.

3. Tailstock: The tailstock is the part of the machine that supports the other end of the workpiece and provides stability during the thread rolling process.

4. Spindle: The spindle is the rotating shaft that holds the thread rolling dies. It is driven by the headstock and rotates the workpiece during the thread rolling process.

5. Thread Rolling Dies: These are the tools that actually form the threads on the workpiece. They are made of hardened steel and come in various sizes and shapes depending on the type of thread to be rolled.

6. Feed Mechanism: The feed mechanism is responsible for moving the thread rolling dies towards and away from the workpiece. It is usually controlled by a hydraulic or mechanical system.

7. Control Panel: The control panel is where the operator can set and adjust the parameters of the thread rolling process, such as the speed, feed rate, and depth of the thread.

8. Lubrication System: Thread rolling machines require a constant supply of lubricant to reduce friction and heat during the rolling process. The lubrication system ensures that the dies and workpiece are properly lubricated.

14.What safety precautions should be taken when operating a vertical thread rolling machine factory?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers.

1. Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and earplugs.

2. Make sure the machine is properly grounded to prevent electrical hazards.

3. Keep the work area clean and free of clutter to avoid tripping hazards.

4. Familiarize yourself with the machine's operating manual and follow all safety instructions.

5. Do not wear loose clothing or jewelry that could get caught in the machine.

6. Always use the correct size and type of dies for the thread being rolled.

7. Do not touch the rotating parts of the machine while it is in operation.

8. Keep your hands and fingers away from the die area and feeding mechanism.

9. Do not attempt to adjust or repair the machine while it is running.

10. Use a push stick or other tool to feed the material into the machine to avoid hand injuries.

11. Do not overload the machine with excessive material.

12. Regularly inspect the machine for any signs of wear or damage and perform maintenance as needed.

13. If the machine malfunctions or makes unusual noises, stop the operation immediately and consult a qualified technician.

14. Always turn off the machine and disconnect the power before performing any maintenance or cleaning.

15. Train all operators on the safe operation of the machine and ensure they follow all safety precautions.

- Place of Origin:

- Video outgoing-inspection:

- Machinery Test Report:

- Marketing Type:

- Warranty of core components:

- Core Components:

- Key Selling Points:

- Applicable Industries:

- Application:

- Condition:

- Production Capacity:

- Voltage: