huide

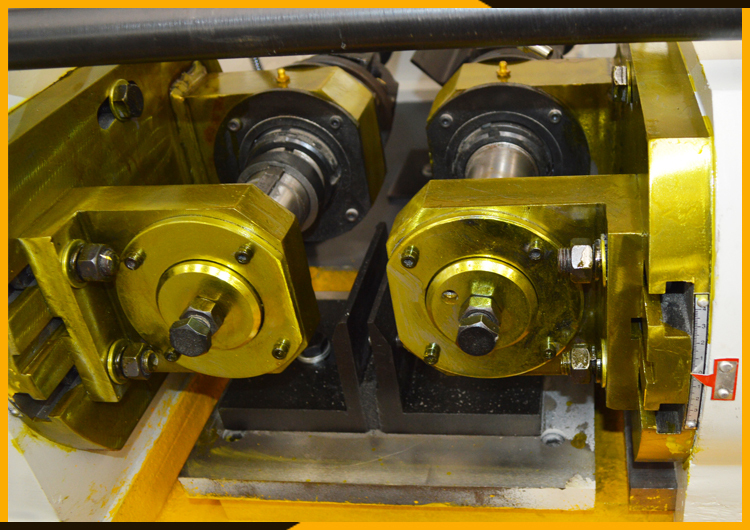

thread rolling machine working

Fengsheng. insists on providing customers with excellent products and professional services, and develops into the most attractive supplier in China, and cooperates with customers all over the world to achieve win-win development.Our products are very popular in Honduras,Bhutan,Navassa Island,Malawi,Turkey,Greece,Saint Lucia, America . have gained great credit from our customers.

Our goal is to making professional and class equipment ,excellent service and top-ranking innovation ,to achieve product specialization ,technical specialization,services professional and team .

| Product name | thread rolling machine working |

| Keyword | thread rolling machine shop local,thread rod rolling machine,discount thread rolling machine,advance thread rolling machine supplier,three shaft thread rolling machine factory,factory price thread rolling machine,screw bolt thread rolling machine |

| Place of Origin | China |

| Production Capacity | 208~400/Per Min |

| Power | 2.2~6kw |

| Thread Dia(mm) | 2.0~4.0 |

| Thread Length(mm) | 6~50 |

| Feature | pipe nipple threading machine in its rolling pressure range of cold, the workpiece for thread, ruled, twill and other treatment; straight, helical and oblique spline gear rolling; straightening, reducing diameter, rolling and various forming rolling. |

| Dimensions | 1546mm*1863mm*1883mm, (Contact us for specific information to confirm) |

| Applicable Industries | Building Material Shops, etc. |

| Color | green or customized |

| Weight | 2402kg |

| Product Description | The machine has a safe and reliable electro-hydraulic execution and control system. Each work cycle can be selected in manual, semi-automatic and automatic ways. |

| terms of packing | enerally, we pack our goods in plywood cases. |

| terms of paymen | T/T 30% as deposit, and 70% balance against BL copy |

| Life span | 16 years (Contact us for specific information to confirm) |

| After-sale service | 12 months warrantly, man-made destory will be exception. |

| thread rolling machine working Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 2449x2060x1726mm(Contact us for specific information to confirm) |

| OEM/ODM | Customization Service Provided |

| Sales country | All over the world for example:Honduras,Bhutan,Navassa Island,Malawi,Turkey,Greece,Saint Lucia |

| MOQ | 5pcs(Contact us for specific information to confirm) |

| Delivery time | 15-20 days for OEM, 5-7days for ready goods. |

thread rolling machine working

huide-machinery.as one of the most professional thread rolling machine working manufacturer has the advantages at:

We are the leader thread rolling machine supplier in China, also we have customers worldwide, such as America, Argentina, Brazil, Belarus, Bangladesh, Honduras,Bhutan,Navassa Island,Malawi,Turkey,Greece,Saint Lucia, and Italy.We are factory specializing in the manufacture and export of thread rolling machine for more than 20 years, all of the production we sale are at a very best price and high quality.

We take care of our product quality, any defect of the goods, we will take responsibility. You are risk-free.And we believe that the good quality products will can give us survival, so, we always offer the top quality products to our customers, to keep them have the competitiveness in there market.

thread rolling machine working services FAQs Guide

Are you looking for a quick review guide about thread rolling machine workingservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding thread rolling machine working services.

Let’s continue!

2.What Types of Materials can be Used with a thread rolling machine working?

3.Is a thread rolling machine working Suitable for High Volume Production?

4.Can a thread rolling machine working be customized for specific production requirements?

5.What are Some Common Applications of Threads Created by a thread rolling machine working?

6. If the machine get damaged, what can I do ?

7.How Does the Size of a thread rolling machine working Affect Production?

8.Can thread rolling be used on already machined parts?

1.What are the Limitations of a thread rolling machine working?

Our thread rolling machine working products undergo strict quality control to ensure customer satisfaction.

1. Limited to cylindrical parts: Thread rolling machines are only suitable for producing threads on cylindrical parts. They cannot be used for producing threads on non-cylindrical or irregularly shaped parts.

2. Limited thread size range: Thread rolling machines have a limited range of thread sizes that they can produce. This is determined by the size of the thread rolling dies used in the machine.

3. Limited thread types: Thread rolling machines are designed to produce only straight threads. They cannot produce tapered or helical threads.

4. High initial cost: Thread rolling machines are expensive to purchase and set up, making them less accessible for small businesses or hobbyists.

5. Limited material compatibility: Thread rolling machines are not suitable for all types of materials. They work best with softer materials such as aluminum, brass, and low carbon steel.

2.What Types of Materials can be Used with a thread rolling machine working?

We continue to invest in research and development and continue to launch innovative products.

1. Metal: Thread rolling machines are primarily used for rolling threads on metal materials such as steel, aluminum, brass, and copper. These materials are commonly used in industries such as automotive, aerospace, and construction.

2. Plastic: Some thread rolling machines are also capable of rolling threads on plastic materials such as nylon, PVC, and acrylic. These materials are commonly used in industries such as electronics, medical, and consumer goods.

3. Wood: Thread rolling machines can also be used to create threads on wooden materials such as hardwood and softwood. These threads are commonly used in furniture making and woodworking industries.

4. Composite materials: Thread rolling machines can also be used to roll threads on composite materials such as carbon fiber, fiberglass, and Kevlar. These materials are commonly used in industries such as aerospace, marine, and sports equipment.

5. Rubber: Some thread rolling machines are also capable of rolling threads on rubber materials such as silicone, neoprene, and EPDM. These materials are commonly used in industries such as automotive, construction, and medical.

6. Ceramic: Thread rolling machines can also be used to create threads on ceramic materials such as porcelain, clay, and glass. These materials are commonly used in industries such as pottery, construction, and electronics.

7. Other materials: Depending on the type and capabilities of the thread rolling machine, it may also be able to roll threads on other materials such as leather, paper, and fabric. These materials are commonly used in industries such as fashion, packaging, and upholstery.

3.Is a thread rolling machine working Suitable for High Volume Production?

We have a professional team that is committed to the innovation and development of thread rolling machine working.

Yes, a thread rolling machine is suitable for high volume production. Thread rolling machines are designed to efficiently and accurately produce threads on a large scale. They are capable of producing threads at a much faster rate than traditional methods such as cutting or grinding. Additionally, thread rolling machines have a longer tool life and require less maintenance, making them ideal for high volume production.

4.Can a thread rolling machine working be customized for specific production requirements?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

Yes, a thread rolling machine can be customized for specific production requirements. This can include changes to the machine's size, speed, thread size and pitch, material compatibility, and other features to meet the specific needs of a production process. Customization can also involve the integration of additional components or automation systems to improve efficiency and productivity. Many manufacturers offer customization services for their thread rolling machines to meet the unique needs of their customers.

5.What are Some Common Applications of Threads Created by a thread rolling machine working?

As one of the top thread rolling machine working manufacturers in China, we take this very seriously.

1. Fasteners: Thread rolling machines are commonly used to create threads on bolts, screws, and other fasteners. This allows for a stronger and more precise thread compared to traditional cutting methods.

2. Automotive Industry: Thread rolling machines are used to create threads on various automotive components such as engine parts, suspension components, and transmission parts.

3. Aerospace Industry: Threads created by thread rolling machines are used in the production of aircraft components such as landing gear, engine parts, and structural components.

4. Construction Industry: Threaded rods and bolts used in construction are often created using thread rolling machines. This ensures a strong and reliable connection between building materials.

5. Medical Industry: Threaded components are used in medical devices such as implants, surgical instruments, and prosthetics. Thread rolling machines are used to create precise and durable threads for these applications.

6. If the machine get damaged, what can I do ?

In the guarantee time (15 months) , we will send the spare parts to you for free and provide the technical consultant for anytime. If more terrible, we can send our engineers to your factory. We will provide same good after-sale service as the pre-sale service. For any of your questions, we will reply within 12 hours.

7.How Does the Size of a thread rolling machine working Affect Production?

We actively participate in the thread rolling machine working industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion

The size of a thread rolling machine can have a significant impact on production in several ways:

1. Capacity: The size of a thread rolling machine determines its capacity, i.e. the maximum size and length of the threads it can produce. A larger machine will have a higher capacity, allowing for the production of larger and longer threads. This can increase production by reducing the need for multiple setups or machine changes.

2. Speed: Generally, larger thread rolling machines have higher production speeds compared to smaller ones. This is because they have more powerful motors and can handle larger workpieces, resulting in faster thread rolling cycles. This can significantly increase production output.

3. Versatility: Smaller thread rolling machines are typically designed for specific thread sizes and types, while larger machines can handle a wider range of thread sizes and types. This versatility allows for the production of a variety of threads without the need for multiple machines, saving time and increasing production efficiency.

4. Setup and changeover time: Larger thread rolling machines often have more advanced features and automation, making setup and changeover between different thread sizes and types faster and more efficient. This reduces downtime and increases production output.

5. Maintenance and downtime: Larger thread rolling machines are generally more robust and have a longer lifespan compared to smaller machines. This means less frequent maintenance and downtime, resulting in increased production.

In summary, the size of a thread rolling machine can affect production by increasing capacity, speed, versatility, and efficiency, while also reducing downtime and maintenance. Choosing the right size machine for your production needs is crucial for maximizing productivity and profitability.

8.Can thread rolling be used on already machined parts?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance.

Yes, thread rolling can be used on already machined parts. However, the part must have a smooth and clean surface in order for the thread rolling process to be successful. Any imperfections or roughness on the surface can affect the quality of the thread formed by the rolling process. Additionally, the part must have the correct dimensions and tolerances to ensure proper thread formation during the rolling process.

- Place of Origin:

- Video outgoing-inspection:

- Machinery Test Report:

- Marketing Type:

- Warranty of core components:

- Core Components:

- Key Selling Points:

- Applicable Industries:

- Application:

- Condition:

- Production Capacity:

- Voltage: