huide

thread rolling machine manufacturer in chennai

Our target customers are all customers from all over world( Guinea-Bissau,Reunion,Montserrat,Costa Rica,Iraq,Turkmenistan,North America, America, Africa and Oceania) who need our product.

We focus on customer focus--Identify customer needs with sincere and professional communication, Strictly control the production process to provide customers with high-quality products, professional technology and after-sales service to provide customers with the best-sales service and guarantee.

| Product name | thread rolling machine manufacturer in chennai |

| Keyword | flatt thread roller machine,thread rolling machine price,hs code for hydraulic thread rolling machine,china thread rolling machine rollers,thread rolling machine suppliers |

| Place of Origin | China |

| Production Capacity | 267~400/Per Min |

| Power | 2.2~6kw |

| Thread Dia(mm) | 2.0~4.0 |

| Thread Length(mm) | 4~50 |

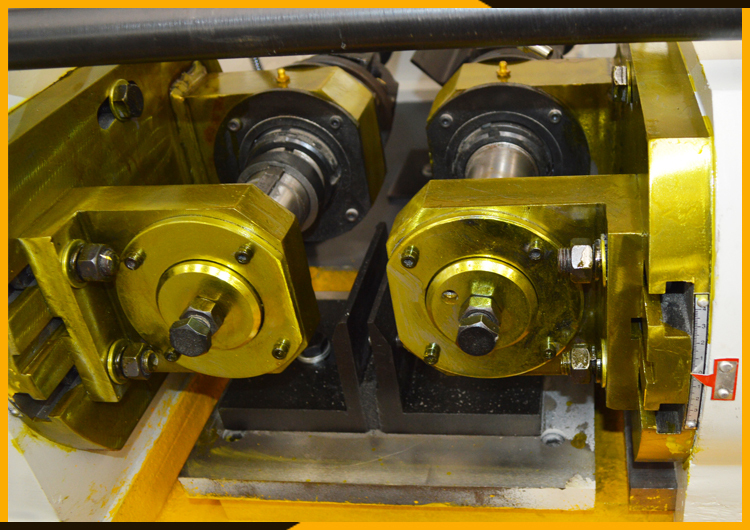

| Feature | pipe nipple threading machine in its rolling pressure range of cold, the workpiece for thread, ruled, twill and other treatment; straight, helical and oblique spline gear rolling; straightening, reducing diameter, rolling and various forming rolling. |

| Dimensions | 1554mm*1943mm*2034mm, (Contact us for specific information to confirm) |

| Applicable Industries | Automotive Manufacturing, etc. |

| Color | Brown or customized |

| Weight | 2371kg |

| Product Description | The machine has a safe and reliable electro-hydraulic execution and control system. Each work cycle can be selected in manual, semi-automatic and automatic ways. |

| terms of packing | enerally, we pack our goods in plywood cases. |

| terms of paymen | T/T 30% as deposit, and 70% balance against BL copy |

| Life span | 18 years (Contact us for specific information to confirm) |

| After-sale service | 12 months warrantly, man-made destory will be exception. |

| thread rolling machine manufacturer in chennai Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 2932x2494x2003mm(Contact us for specific information to confirm) |

| OEM/ODM | Customization Service Provided |

| Sales country | All over the world for example:Guinea-Bissau,Reunion,Montserrat,Costa Rica,Iraq,Turkmenistan |

| MOQ | 1pcs(Contact us for specific information to confirm) |

| Delivery time | 15-20 days for OEM, 5-7days for ready goods. |

thread rolling machine manufacturer in chennai

huide-machinery.as one of the most professional thread rolling machine manufacturer in chennai manufacturer has the advantages at:

We are the leader thread rolling machine supplier in China, also we have customers worldwide, such as America, Argentina, Brazil, Belarus, Bangladesh, Guinea-Bissau,Reunion,Montserrat,Costa Rica,Iraq,Turkmenistan, and Italy.We are factory specializing in the manufacture and export of thread rolling machine for more than 20 years, all of the production we sale are at a very best price and high quality.

We take care of our product quality, any defect of the goods, we will take responsibility. You are risk-free.And we believe that the good quality products will can give us survival, so, we always offer the top quality products to our customers, to keep them have the competitiveness in there market.

thread rolling machine manufacturer in chennai services FAQs Guide

Are you looking for a quick review guide about thread rolling machine manufacturer in chennaiservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding thread rolling machine manufacturer in chennai services.

Let’s continue!

2.What Quality Control Measures are Used in thread rolling machine manufacturer in chennai Production?

3.Can a thread rolling machine manufacturer in chennai handle different thread types such as ACO, UNF, or NPT?

4.Is a thread rolling machine manufacturer in chennai Suitable for High Volume Production?

5.What is the Typical Lifespan of a thread rolling machine manufacturer in chennai?

6.What is the difference between thread rolling and thread cutting?

7.How can a thread rolling machine manufacturer in chennai improve the efficiency of my production process?

8.Are There Different Types of Thread Rolling Dies?

9.What are the Advantages of Using a thread rolling machine manufacturer in chennai in Production?

10.How does a thread rolling machine manufacturer in chennai contribute to the accuracy and precision of threaded parts?

11.Can a thread rolling machine manufacturer in chennai Create Threads on Hard Materials?

1.What are Some Common Applications of Threads Created by a thread rolling machine manufacturer in chennai?

As one of the top thread rolling machine manufacturer in chennai manufacturers in China, we take this very seriously.

1. Fasteners: Thread rolling machines are commonly used to create threads on bolts, screws, and other fasteners. This allows for a stronger and more precise thread compared to traditional cutting methods.

2. Automotive Industry: Thread rolling machines are used to create threads on various automotive components such as engine parts, suspension components, and transmission parts.

3. Aerospace Industry: Threads created by thread rolling machines are used in the production of aircraft components such as landing gear, engine parts, and structural components.

4. Construction Industry: Threaded rods and bolts used in construction are often created using thread rolling machines. This ensures a strong and reliable connection between building materials.

5. Medical Industry: Threaded components are used in medical devices such as implants, surgical instruments, and prosthetics. Thread rolling machines are used to create precise and durable threads for these applications.

2.What Quality Control Measures are Used in thread rolling machine manufacturer in chennai Production?

1. Material Inspection: The first step in quality control is to inspect the raw materials used in the production of thread rolling machines. This includes checking the quality and specifications of the steel, bearings, gears, and other components.

2. Machine Calibration: Before starting the production process, the thread rolling machine is calibrated to ensure that it is functioning properly and producing accurate threads.

3. In-process Inspection: During the production process, regular inspections are carried out to check the dimensions, surface finish, and other critical parameters of the thread rolling machine.

4. Statistical Process Control (SPC): SPC is a method used to monitor and control the production process by collecting and analyzing data. This helps to identify any variations or defects in the production process and take corrective actions.

5. Final Inspection: Once the thread rolling machine is completed, a final inspection is carried out to ensure that it meets all the required specifications and standards.

6. Performance Testing: The thread rolling machine is tested for its performance by running it with different types of materials and thread sizes to ensure that it can produce accurate and consistent threads.

7. Quality Management System: Most manufacturers have a quality management system in place to ensure that all the processes and procedures are followed correctly and any issues are addressed promptly.

3.Can a thread rolling machine manufacturer in chennai handle different thread types such as ACO, UNF, or NPT?

Our mission is to provide customers with the best solutions for thread rolling machine manufacturer in chennai.

Yes, a thread rolling machine can handle different thread types such as ACO, UNF, or NPT. These machines are designed to be versatile and can be adjusted to produce different thread types by changing the dies or adjusting the machine settings. However, it is important to note that some thread rolling machines may be specifically designed for certain thread types, so it is important to check the machine's capabilities before use.

4.Is a thread rolling machine manufacturer in chennai Suitable for High Volume Production?

We have a professional team that is committed to the innovation and development of thread rolling machine manufacturer in chennai.

Yes, a thread rolling machine is suitable for high volume production. Thread rolling machines are designed to efficiently and accurately produce threads on a large scale. They are capable of producing threads at a much faster rate than traditional methods such as cutting or grinding. Additionally, thread rolling machines have a longer tool life and require less maintenance, making them ideal for high volume production.

5.What is the Typical Lifespan of a thread rolling machine manufacturer in chennai?

The typical lifespan of a thread rolling machine can vary depending on several factors such as usage, maintenance, and quality of the machine. However, on average, a thread rolling machine can last for 10-15 years with proper care and maintenance. Some high-quality machines can even last for 20-25 years. Regular maintenance and timely repairs can also extend the lifespan of a thread rolling machine.

6.What is the difference between thread rolling and thread cutting?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

Thread rolling and thread cutting are two different methods used to create threads on a workpiece. The main difference between them lies in the way the threads are formed.

Thread rolling is a cold forming process in which a hardened steel die is pressed against the surface of a rotating workpiece. The pressure from the die creates the threads on the workpiece by displacing the material. This process is typically used for creating external threads on cylindrical parts, such as bolts, screws, and studs. It is a highly efficient and precise method that produces strong and accurate threads.

On the other hand, thread cutting is a machining process in which a cutting tool is used to remove material from the workpiece to create threads. The cutting tool is usually a tap or a die, and it is rotated or moved along the workpiece to cut the threads. This process is commonly used for creating internal threads on holes or external threads on shafts. It is a slower process compared to thread rolling, but it allows for more flexibility in terms of thread size and shape.

In summary, thread rolling is a cold forming process that uses pressure to create threads, while thread cutting is a machining process that uses cutting tools to remove material and create threads. Both methods have their advantages and are used in different applications depending on the requirements.

7.How can a thread rolling machine manufacturer in chennai improve the efficiency of my production process?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

1. Faster Production Speed: Thread rolling machines are designed to quickly and efficiently create threads on a variety of materials. This can significantly increase the speed of your production process, allowing you to produce more products in a shorter amount of time.

2. Consistent Quality: Thread rolling machines use a precise and controlled process to create threads, resulting in consistent and accurate thread dimensions. This eliminates the need for manual threading, which can be prone to human error and result in inconsistent thread quality.

3. Reduced Labor Costs: With a thread rolling machine, you can automate the threading process, reducing the need for manual labor. This can save you money on labor costs and allow your employees to focus on other tasks.

4. Versatility: Thread rolling machines can create threads on a wide range of materials, including steel, aluminum, and plastic. This versatility allows you to use the same machine for different products, reducing the need for multiple machines and saving space in your production facility.

5. Longer Tool Life: Thread rolling machines use hardened dies to create threads, which can last much longer than traditional threading tools. This means you will spend less time and money on replacing worn-out tools, further improving the efficiency of your production process.

6. Reduced Material Waste: With traditional threading methods, excess material is often removed to create the threads. This can result in a significant amount of material waste. Thread rolling machines, on the other hand, use a cold forming process that does not require material removal, reducing waste and saving you money on material costs.

7. Easy to Use: Thread rolling machines are designed to be user-friendly and easy to operate. This means that even employees with minimal training can quickly learn how to use the machine, reducing the time and resources needed for training.

8. Lower Maintenance Costs: Thread rolling machines are built to be durable and require minimal maintenance. This can save you money on maintenance costs and reduce downtime in your production process.

9. Improved Safety: Manual threading can be a hazardous task, as it involves handling sharp tools and working with rotating machinery. By automating the threading process with a thread rolling machine, you can improve the safety of your production process and reduce the risk of workplace injuries.

10. Cost Savings: Overall, the increased efficiency and productivity of using a thread rolling machine can result in significant cost savings for your production process. This can help you stay competitive in the market and increase your profitability.

8.Are There Different Types of Thread Rolling Dies?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system.

Yes, there are different types of thread rolling dies, including:

1. Flat dies: These are the most common type of thread rolling dies and are used for producing external threads on cylindrical parts.

2. Circular dies: These dies have a curved profile and are used for producing threads on conical or tapered parts.

3. Planetary dies: These dies have multiple thread profiles on a single die and are used for producing threads on complex or non-cylindrical parts.

4. Rack dies: These dies have a straight, toothed profile and are used for producing threads on long, thin parts such as screws or bolts.

5. Knurling dies: These dies have a serrated profile and are used for producing knurled patterns on cylindrical parts.

6. Thread forming dies: These dies do not cut material but instead deform it to create threads. They are used for producing threads on soft or brittle materials.

7. Combination dies: These dies have multiple thread profiles on a single die and can be used for both rolling and cutting threads.

8. Adjustable dies: These dies have adjustable thread profiles and are used for producing threads of different sizes on the same die.

9. Tapered dies: These dies have a tapered profile and are used for producing tapered threads on parts such as pipes or fittings.

10. Thread chasers: These dies are used for repairing damaged threads on existing parts. They have a cutting profile that matches the damaged thread and can be used to restore it to its original size and shape.

9.What are the Advantages of Using a thread rolling machine manufacturer in chennai in Production?

We focus on providing high thread rolling machine manufacturer in chennai quality products and services.

1. Increased Efficiency: Thread rolling machines are designed to produce threads at a much faster rate compared to traditional methods such as cutting or grinding. This results in increased production efficiency and reduced production time.

2. Cost-effective: Thread rolling machines are cost-effective as they require less maintenance and have a longer lifespan compared to other methods. They also use less energy, resulting in lower operating costs.

3. Consistency and Accuracy: Thread rolling machines produce threads with high precision and consistency, ensuring that each thread is of the same quality. This reduces the chances of errors and rejections, resulting in cost savings for the company.

4. Versatility: Thread rolling machines can produce a wide range of threads, including straight, tapered, and parallel threads. They can also be used to produce threads on a variety of materials, including steel, aluminum, and plastic.

5. Improved Strength: Threads produced by thread rolling machines have a higher tensile strength compared to threads produced by cutting or grinding. This makes them more durable and suitable for use in high-stress applications.

6. Reduced Material Waste: Thread rolling machines produce threads by displacing the material rather than removing it. This results in less material waste, making it a more environmentally friendly option.

7. Easy to Operate: Thread rolling machines are easy to operate and require minimal training. This makes it easier for companies to train their employees and ensure consistent production quality.

10.How does a thread rolling machine manufacturer in chennai contribute to the accuracy and precision of threaded parts?

We are committed to providing personalized solutions and established long -term strategic cooperative relationships with customers.

A thread rolling machine contributes to the accuracy and precision of threaded parts in several ways:

1. Consistent Thread Profile: Thread rolling machines use a set of dies to form the threads on a workpiece. These dies are precisely machined to create a specific thread profile, ensuring that each thread is identical in shape and size. This results in a more accurate and precise thread compared to other methods such as cutting or grinding.

2. Uniform Thread Pitch: The dies on a thread rolling machine are designed to maintain a constant thread pitch throughout the entire length of the thread. This ensures that the threads are evenly spaced and have a consistent depth, leading to better accuracy and precision.

3. Reduced Material Deformation: Thread rolling machines use a cold forming process, where the material is not subjected to high temperatures. This reduces the risk of material deformation, which can affect the accuracy and precision of the threads.

4. Tight Tolerances: Thread rolling machines are capable of producing threads with tight tolerances, often within a few thousandths of an inch. This level of precision is difficult to achieve with other methods, making thread rolling a preferred choice for high-precision applications.

5. Repeatable Results: The use of dies and a controlled process in thread rolling ensures that the same results are achieved every time. This makes it easier to produce large quantities of threaded parts with consistent accuracy and precision.

Overall, a thread rolling machine offers a more controlled and precise method of creating threads, resulting in higher accuracy and precision of threaded parts. This makes it a preferred choice for industries such as automotive, aerospace, and medical, where precision is critical.

11.Can a thread rolling machine manufacturer in chennai Create Threads on Hard Materials?

Yes, a thread rolling machine can create threads on hard materials. Thread rolling is a cold forming process that uses pressure to deform the material and create threads. This process is suitable for both soft and hard materials, including steel, stainless steel, titanium, and other alloys. The pressure applied by the thread rolling machine can be adjusted to accommodate the hardness of the material, ensuring that the threads are formed without damaging the material. Additionally, thread rolling can produce stronger and more precise threads compared to other methods such as cutting or tapping, making it a preferred method for creating threads on hard materials.

- Place of Origin:

- Video outgoing-inspection:

- Machinery Test Report:

- Marketing Type:

- Warranty of core components:

- Core Components:

- Key Selling Points:

- Applicable Industries:

- Application:

- Condition:

- Production Capacity:

- Voltage: