huide

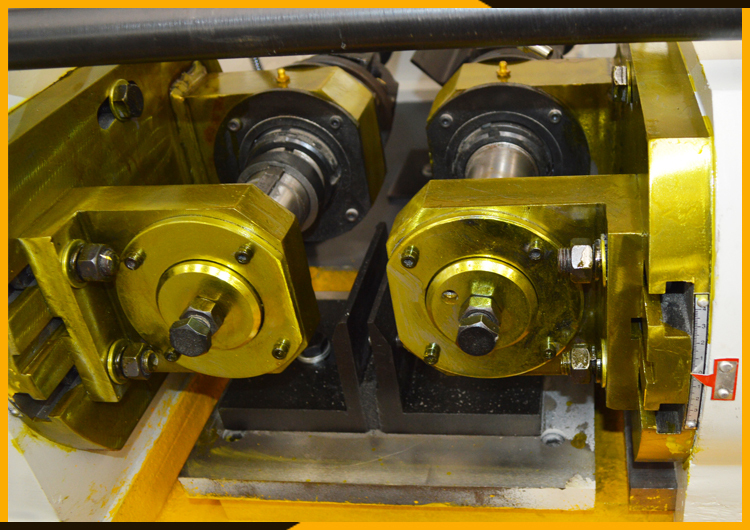

thread rolling die making machine

Our products have been exported to Europe, America, Asia, Tunisia,British Indian Ocean Territory,Puerto Rico,Jordan,Namibia. OEM service is also available. And all of our products have been have the patent. So we can make all your idea design that you want.

| Product name | thread rolling die making machine |

| Keyword | china two rollers hydraulic thread rolling machine,thread rolling machine,thread rolling machine for bolt,thread rolling machine for sale uk,thread rolling machines for sale uk,auto feeding thread rolling machine,thread rolling machine factory |

| Place of Origin | China |

| Production Capacity | 219~400/Per Min |

| Power | 2.2~6kw |

| Thread Dia(mm) | 2.0~4.0 |

| Thread Length(mm) | 8~50 |

| Feature | pipe nipple threading machine in its rolling pressure range of cold, the workpiece for thread, ruled, twill and other treatment; straight, helical and oblique spline gear rolling; straightening, reducing diameter, rolling and various forming rolling. |

| Dimensions | 1771mm*1581mm*1615mm, (Contact us for specific information to confirm) |

| Applicable Industries | Machinery Repair Shops, etc. |

| Color | purple or customized |

| Weight | 2422kg |

| Product Description | The machine has a safe and reliable electro-hydraulic execution and control system. Each work cycle can be selected in manual, semi-automatic and automatic ways. |

| terms of packing | enerally, we pack our goods in plywood cases. |

| terms of paymen | T/T 30% as deposit, and 70% balance against BL copy |

| Life span | 14 years (Contact us for specific information to confirm) |

| After-sale service | 12 months warrantly, man-made destory will be exception. |

| thread rolling die making machine Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 2732x2298x1931mm(Contact us for specific information to confirm) |

| OEM/ODM | Customization Service Provided |

| Sales country | All over the world for example:Tunisia,British Indian Ocean Territory,Puerto Rico,Jordan,Namibia |

| MOQ | 1pcs(Contact us for specific information to confirm) |

| Delivery time | 15-20 days for OEM, 5-7days for ready goods. |

thread rolling die making machine

huide-machinery.as one of the most professional thread rolling die making machine manufacturer has the advantages at:

We are the leader thread rolling machine supplier in China, also we have customers worldwide, such as America, Argentina, Brazil, Belarus, Bangladesh, Tunisia,British Indian Ocean Territory,Puerto Rico,Jordan,Namibia, and Italy.We are factory specializing in the manufacture and export of thread rolling machine for more than 20 years, all of the production we sale are at a very best price and high quality.

We take care of our product quality, any defect of the goods, we will take responsibility. You are risk-free.And we believe that the good quality products will can give us survival, so, we always offer the top quality products to our customers, to keep them have the competitiveness in there market.

thread rolling die making machine services FAQs Guide

Are you looking for a quick review guide about thread rolling die making machineservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding thread rolling die making machine services.

Let’s continue!

2.What materials can be used with a thread rolling die making machine?

3.What are the Safety Precautions when Operating a thread rolling die making machine?

4.What is the maximum thread size that can be rolled with this machine?

5.What does your factory produce ?

6.How Does the Size and Shape of Threads Created by a thread rolling die making machine Affect Their Performance?

7.Is a thread rolling die making machine Suitable for High Volume Production?

8.What is the Difference Between Annular and Circular Thread Rolling?

1.What are the Different thread rolling die making machine Drive Types?

Being one of the top thread rolling die making machine manufacturers in China, We attach great importance to this detail.

1. Mechanical Drive: This type of drive uses a motor and gears to power the thread rolling machine. The motor drives the gears, which in turn rotate the dies to create the threads.

2. Hydraulic Drive: In this type of drive, a hydraulic pump is used to power the thread rolling machine. The pump creates pressure, which is used to rotate the dies and create the threads.

3. Pneumatic Drive: A pneumatic drive uses compressed air to power the thread rolling machine. The air is used to rotate the dies and create the threads.

4. Servo Drive: This type of drive uses a servo motor to power the thread rolling machine. The motor is controlled by a computer, which allows for precise control over the rotation of the dies.

5. Electric Drive: An electric drive uses an electric motor to power the thread rolling machine. The motor is connected to the dies and rotates them to create the threads.

6. Direct Drive: In this type of drive, the dies are directly connected to the motor without any gears or other components. This allows for a more efficient transfer of power and faster thread rolling.

7. Belt Drive: A belt drive uses a belt to transfer power from the motor to the dies. This type of drive is commonly used in smaller thread rolling machines.

8. Chain Drive: Similar to a belt drive, a chain drive uses a chain to transfer power from the motor to the dies. This type of drive is commonly used in larger thread rolling machines.

2.What materials can be used with a thread rolling die making machine?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced thread rolling die making machine products.

1. Steel: Thread rolling machines are commonly used for rolling threads on steel materials, including carbon steel, alloy steel, and stainless steel.

2. Aluminum: Aluminum is another commonly used material with thread rolling machines. It is lightweight, strong, and has good corrosion resistance, making it suitable for various applications.

3. Brass: Brass is a soft and malleable material that is often used for decorative purposes. It can also be rolled into threads using a thread rolling machine.

4. Copper: Copper is a highly conductive and ductile material that is commonly used in electrical and plumbing applications. It can also be rolled into threads using a thread rolling machine.

5. Titanium: Titanium is a strong and lightweight material that is commonly used in aerospace and medical industries. It can also be rolled into threads using a thread rolling machine.

6. Plastics: Some thread rolling machines are designed to work with plastic materials, such as nylon, PVC, and polyethylene. These materials are commonly used in the production of plastic fasteners and fittings.

7. Composite materials: Thread rolling machines can also be used to roll threads on composite materials, such as fiberglass, carbon fiber, and Kevlar. These materials are commonly used in the aerospace and automotive industries.

8. Other materials: Other materials that can be used with a thread rolling machine include bronze, cast iron, and various types of alloys. The suitability of these materials will depend on the specific machine and its capabilities.

3.What are the Safety Precautions when Operating a thread rolling die making machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

1. Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and earplugs to protect against flying debris and noise.

2. Make sure the machine is properly grounded to prevent electrical hazards.

3. Before starting the machine, ensure that all guards and safety devices are in place and functioning properly.

4. Keep the work area clean and free of clutter to prevent tripping hazards.

5. Do not wear loose clothing or jewelry that could get caught in the machine.

6. Familiarize yourself with the machine's operating manual and follow all safety instructions.

7. Never operate the machine if you are fatigued or under the influence of drugs or alcohol.

8. Do not attempt to adjust or repair the machine while it is in operation.

9. Use the correct size and type of thread rolling dies for the material being worked on.

10. Always use a push stick or other tool to feed the material into the machine to keep your hands and fingers away from the moving parts.

11. Do not touch the rotating parts of the machine while it is in operation.

12. If the machine jams or malfunctions, turn off the power and wait for all moving parts to come to a complete stop before attempting to fix the issue.

13. Regularly inspect the machine for any signs of wear or damage and perform maintenance as recommended by the manufacturer.

14. Only trained and authorized personnel should operate the thread rolling machine.

15. In case of an emergency, know the location of the emergency stop button and how to use it.

4.What is the maximum thread size that can be rolled with this machine?

As one of the top thread rolling die making machine manufacturers in China, we take this very seriously.

The maximum thread size that can be rolled with this machine depends on the specific model and specifications of the machine. It is best to consult the manufacturer or the machine's manual for the exact maximum thread size.

5.What does your factory produce ?

We produce and export all kinds of Reinforced Bar Thread Rolling Machine with butt welding. We also can design and develop automatic wire ring making machines with butt welding according to your requirements.

6.How Does the Size and Shape of Threads Created by a thread rolling die making machine Affect Their Performance?

The size and shape of threads created by a thread rolling machine can greatly affect their performance in various ways. Some of the key factors that are influenced by the size and shape of threads include strength, durability, and compatibility with other components.

1. Strength: The size and shape of threads play a crucial role in determining their strength. Threads with larger diameters and deeper crests tend to be stronger and more resistant to shear forces. This is because they have a larger cross-sectional area, which allows them to distribute the load more evenly and withstand higher levels of stress.

2. Durability: The size and shape of threads also affect their durability. Threads with larger diameters and deeper crests are less prone to wear and tear, as they have a larger surface area in contact with the mating component. This reduces the pressure on individual threads and helps to distribute the load more evenly, thereby increasing their lifespan.

3. Compatibility: The size and shape of threads also determine their compatibility with other components. Threads that are too large or too small may not fit properly with the mating component, leading to issues such as thread stripping or loosening. Additionally, threads with irregular shapes or poor surface finish may not provide a tight and secure fit, which can affect the overall performance of the assembly.

4. Thread engagement: The size and shape of threads also affect the amount of thread engagement, which is the length of the thread that is in contact with the mating component. Threads with larger diameters and deeper crests have a longer thread engagement, which provides a stronger and more secure connection between the components.

In conclusion, the size and shape of threads created by a thread rolling machine can have a significant impact on their performance. It is important to carefully consider these factors when designing and manufacturing threaded components to ensure optimal strength, durability, and compatibility.

7.Is a thread rolling die making machine Suitable for High Volume Production?

We have a professional team that is committed to the innovation and development of thread rolling die making machine.

Yes, a thread rolling machine is suitable for high volume production. Thread rolling machines are designed to efficiently and accurately produce threads on a large scale. They are capable of producing threads at a much faster rate than traditional methods such as cutting or grinding. Additionally, thread rolling machines have a longer tool life and require less maintenance, making them ideal for high volume production.

8.What is the Difference Between Annular and Circular Thread Rolling?

We have been working hard to improve service quality and meet customer needs.

Annular and circular thread rolling are two methods used to create threads on cylindrical parts. The main difference between these two methods lies in the shape of the thread produced.

Annular thread rolling is a process in which a cylindrical part is rotated between two dies, one of which has a thread-shaped groove. As the part is rotated, the dies move together, pressing the thread-shaped groove into the surface of the part, creating a helical thread. This method produces threads with a triangular cross-section, with rounded peaks and valleys.

On the other hand, circular thread rolling is a process in which a cylindrical part is rotated between two dies, both of which have thread-shaped grooves. As the part is rotated, the dies move together, pressing the thread-shaped grooves into the surface of the part, creating a helical thread. This method produces threads with a circular cross-section, with sharp peaks and valleys.

In summary, the main difference between annular and circular thread rolling is the shape of the thread produced. Annular thread rolling produces triangular threads, while circular thread rolling produces circular threads. The choice between these two methods depends on the specific requirements of the application and the desired thread shape.

- Place of Origin:

- Video outgoing-inspection:

- Machinery Test Report:

- Marketing Type:

- Warranty of core components:

- Core Components:

- Key Selling Points:

- Applicable Industries:

- Application:

- Condition:

- Production Capacity:

- Voltage: