huide

automatic thread rolling machine video

before main focus on China market, have good reputation in domestic market. Now Made in China Machine represent higher performance, HUIDE( Fengsheng )®️ open the oversea market, at present HUIDE( Fengsheng )®️ already export the machine more than 60 countries in the world.such as,Guyana,United Kingdom,Gabon,Armenia,Venezuela,Austria,Namibia,Algeria,Asia,Europe,Oceania‘’etc.

| Product name | automatic thread rolling machine video |

| Keyword | rebar thread rolling machine manufacturers,thread rolling machine uk,thread rolling machines for sale uk,china thread rod rolling machine,vertical thread rolling machine factory,three-axis thread rolling machine factory |

| Place of Origin | China |

| Production Capacity | 221~400/Per Min |

| Power | 2.2~6kw |

| Thread Dia(mm) | 2.0~4.0 |

| Core Components | Motor |

| Thread Length(mm) | 5~50 |

| Condition | New |

| Pre-Sales Service | Inquiry and consulting support. View our Factory. |

| Feature | pipe nipple threading machine in its rolling pressure range of cold, the workpiece for thread, ruled, twill and other treatment; straight, helical and oblique spline gear rolling; straightening, reducing diameter, rolling and various forming rolling. |

| Dimensions | 1659mm*1518mm*1742mm, (Contact us for specific information to confirm) |

| Applicable Industries | Construction works , etc. |

| Advantages | automatic thread rolling machine video--It can be used to process scerw and rebar.The rebar processed by the machine has the good overall mechanical.It can make the tensile strength increased by 20%-30%,the fatigue strength increased by 40%-60%,corrosion resistance increased by 50%-200%.Mechanical properties of rebar connector reached and more than international standards. |

| Weight | 2145kg |

| Product Description | The machine has a safe and reliable electro-hydraulic execution and control system. Each work cycle can be selected in manual, semi-automatic and automatic ways. |

| terms of packing | enerally, we pack our goods in plywood cases. |

| terms of paymen | T/T 30% as deposit, and 70% balance against BL copy |

| Life span | 15 years (Contact us for specific information to confirm) |

| After-sale service | 12 months warrantly, man-made destory will be exception. |

| automatic thread rolling machine video Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 2035x2103x1771mm(Contact us for specific information to confirm) |

| OEM/ODM | Customization Service Provided |

| Sales country | All over the world for example:Guyana,United Kingdom,Gabon,Armenia,Venezuela,Austria,Namibia,Algeria |

| MOQ | 8pcs(Contact us for specific information to confirm) |

| Delivery time | 15-20 days for OEM, 5-7days for ready goods. |

automatic thread rolling machine video

huide-machinery.as one of the most professional automatic thread rolling machine video manufacturer has the advantages at:

We are the leader thread rolling machine supplier in China, also we have customers worldwide, such as America, Argentina, Brazil, Belarus, Bangladesh, Guyana,United Kingdom,Gabon,Armenia,Venezuela,Austria,Namibia,Algeria, and Italy.We are factory specializing in the manufacture and export of thread rolling machine for more than 20 years, all of the production we sale are at a very best price and high quality.

We take care of our product quality, any defect of the goods, we will take responsibility. You are risk-free.And we believe that the good quality products will can give us survival, so, we always offer the top quality products to our customers, to keep them have the competitiveness in there market.

automatic thread rolling machine video services FAQs Guide

Are you looking for a quick review guide about automatic thread rolling machine videoservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding automatic thread rolling machine video services.

Let’s continue!

2.Is the thread rolling process more cost-effective than traditional machining methods?

3.Can a automatic thread rolling machine video Create Threads with Different Tolerances?

4.What are Some Common Defects in Threads Created by a automatic thread rolling machine video?

5.What is the Difference Between Annular and Circular Thread Rolling?

6.How Accurate are Threads Created by a automatic thread rolling machine video?

7.Is a automatic thread rolling machine video Suitable for High Volume Production?

8.How does the thread rolling process compare to other methods such as chasing or grinding?

9.Can a automatic thread rolling machine video Create Threads on Hard Materials?

10.Can a automatic thread rolling machine video handle different thread types such as ACO, UNF, or NPT?

11.What are the Main Components of a automatic thread rolling machine video?

12.What are Some Common Applications of Threads Created by a automatic thread rolling machine video?

1.Is training required to operate a automatic thread rolling machine video?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of automatic thread rolling machine video products.

Yes, training is required to operate a thread rolling machine. This is because thread rolling machines are complex and potentially dangerous machines that require proper knowledge and skills to operate safely and effectively. Training may be provided by the manufacturer or a certified trainer and typically covers topics such as machine setup, operation, maintenance, and safety procedures. It is important for operators to receive proper training to ensure the quality of the threaded products and to prevent accidents or injuries.

2.Is the thread rolling process more cost-effective than traditional machining methods?

We are a new automatic thread rolling machine video manufacturer.

Yes, the thread rolling process is generally more cost-effective than traditional machining methods for producing threads. This is because thread rolling is a faster and more efficient process that requires less material and labor compared to traditional machining methods such as cutting or grinding. Additionally, thread rolling produces stronger and more precise threads, reducing the need for additional finishing processes.

3.Can a automatic thread rolling machine video Create Threads with Different Tolerances?

Yes, a thread rolling machine can create threads with different tolerances. The machine can be adjusted to produce threads with different pitch, diameter, and depth, which ultimately affects the tolerance of the thread. The operator can also adjust the pressure and speed of the machine to achieve the desired tolerance. However, it is important to note that the accuracy and consistency of the thread rolling machine play a crucial role in achieving the desired tolerance. Regular maintenance and calibration of the machine are necessary to ensure consistent and accurate thread production.

4.What are Some Common Defects in Threads Created by a automatic thread rolling machine video?

1. Incomplete Threads: This is a common defect where the thread is not fully formed or is missing in certain areas. This can be caused by improper alignment of the thread rolling machine or worn out dies.

2. Oversized Threads: This defect occurs when the thread is larger than the specified size. It can be caused by excessive pressure or incorrect die settings.

3. Undersized Threads: This is the opposite of oversized threads, where the thread is smaller than the specified size. It can be caused by insufficient pressure or worn out dies.

4. Tapered Threads: Tapered threads have a gradual change in diameter along the length of the thread. This can be caused by misalignment of the dies or uneven pressure during the rolling process.

5. Misaligned Threads: This defect occurs when the threads are not straight and parallel to each other. It can be caused by misalignment of the dies or improper setup of the machine.

6. Thread Flaking: Thread flaking is when small pieces of the thread break off, resulting in a rough and uneven surface. This can be caused by worn out or damaged dies.

7. Thread Cracks: Cracks in the thread can occur due to excessive pressure or improper die settings. This defect can weaken the thread and lead to failure under stress.

8. Thread Galling: Galling is a form of wear that occurs when two surfaces rub against each other. It can cause the thread to seize up and become difficult to turn.

9. Thread Stripping: This defect occurs when the thread is stripped or torn off the surface of the material. It can be caused by excessive pressure or incorrect die settings.

10. Thread Runout: Thread runout is when the thread is not concentric with the axis of the material. This can be caused by misalignment of the dies or uneven pressure during the rolling process.

5.What is the Difference Between Annular and Circular Thread Rolling?

We have been working hard to improve service quality and meet customer needs.

Annular and circular thread rolling are two methods used to create threads on cylindrical parts. The main difference between these two methods lies in the shape of the thread produced.

Annular thread rolling is a process in which a cylindrical part is rotated between two dies, one of which has a thread-shaped groove. As the part is rotated, the dies move together, pressing the thread-shaped groove into the surface of the part, creating a helical thread. This method produces threads with a triangular cross-section, with rounded peaks and valleys.

On the other hand, circular thread rolling is a process in which a cylindrical part is rotated between two dies, both of which have thread-shaped grooves. As the part is rotated, the dies move together, pressing the thread-shaped grooves into the surface of the part, creating a helical thread. This method produces threads with a circular cross-section, with sharp peaks and valleys.

In summary, the main difference between annular and circular thread rolling is the shape of the thread produced. Annular thread rolling produces triangular threads, while circular thread rolling produces circular threads. The choice between these two methods depends on the specific requirements of the application and the desired thread shape.

6.How Accurate are Threads Created by a automatic thread rolling machine video?

We are centered on customers and always pay attention to customers' needs for automatic thread rolling machine video products.

Threads created by a thread rolling machine are highly accurate and precise. This is because thread rolling is a cold forming process that uses pressure to deform the material into the desired thread shape. This results in a thread with a smooth surface and consistent dimensions.

The accuracy of threads created by a thread rolling machine depends on several factors such as the quality of the machine, the material being rolled, and the skill of the operator. However, in general, thread rolling machines can produce threads with tolerances as tight as 0.0005 inches.

Compared to other methods of creating threads, such as cutting or grinding, thread rolling offers superior accuracy and consistency. This is because the material is not removed during the process, resulting in a stronger and more precise thread.

In addition, thread rolling machines are designed to produce threads with high repeatability, meaning that each thread produced will be nearly identical to the previous one. This makes them ideal for high-volume production of threaded parts.

Overall, the accuracy of threads created by a thread rolling machine is very high, making it a preferred method for creating threads in various industries such as automotive, aerospace, and construction.

7.Is a automatic thread rolling machine video Suitable for High Volume Production?

We have a professional team that is committed to the innovation and development of automatic thread rolling machine video.

Yes, a thread rolling machine is suitable for high volume production. Thread rolling machines are designed to efficiently and accurately produce threads on a large scale. They are capable of producing threads at a much faster rate than traditional methods such as cutting or grinding. Additionally, thread rolling machines have a longer tool life and require less maintenance, making them ideal for high volume production.

8.How does the thread rolling process compare to other methods such as chasing or grinding?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced automatic thread rolling machine video products.

Thread rolling is a cold forming process that uses hardened steel dies to deform the surface of a cylindrical blank, creating the desired thread profile. This process is typically used for high volume production of precision threads and offers several advantages over other methods such as chasing or grinding.

1. Faster Production Speed: Thread rolling is a high-speed process that can produce threads at a rate of up to 1000 parts per minute. This is significantly faster than chasing or grinding, which are typically slower processes.

2. Improved Thread Strength: The cold forming process of thread rolling results in a work-hardened surface that is stronger and more durable than threads produced by chasing or grinding. This makes thread rolling ideal for applications that require high strength and reliability.

3. Better Surface Finish: Thread rolling produces a smooth and precise thread surface, which is important for applications that require a tight fit or smooth movement. Chasing and grinding can result in rougher surfaces that may require additional finishing processes.

4. Cost-Effective: Thread rolling is a cost-effective process, especially for high volume production. The use of hardened steel dies also makes it a more durable and long-lasting method compared to chasing or grinding, which may require frequent replacement of tools.

5. Versatility: Thread rolling can be used to produce a wide range of thread sizes and profiles, making it a versatile process for various applications. It can also be used on a variety of materials, including steel, aluminum, and plastic.

In comparison, chasing and grinding are more suitable for smaller production runs or for repairing damaged threads. They also require more skilled labor and may result in higher costs for tooling and setup. However, they may be more suitable for producing specialized or non-standard thread profiles.

Overall, thread rolling offers a faster, more cost-effective, and versatile method for producing high-quality threads, making it a preferred choice for many industrial applications.

9.Can a automatic thread rolling machine video Create Threads on Hard Materials?

Yes, a thread rolling machine can create threads on hard materials. Thread rolling is a cold forming process that uses pressure to deform the material and create threads. This process is suitable for both soft and hard materials, including steel, stainless steel, titanium, and other alloys. The pressure applied by the thread rolling machine can be adjusted to accommodate the hardness of the material, ensuring that the threads are formed without damaging the material. Additionally, thread rolling can produce stronger and more precise threads compared to other methods such as cutting or tapping, making it a preferred method for creating threads on hard materials.

10.Can a automatic thread rolling machine video handle different thread types such as ACO, UNF, or NPT?

Our mission is to provide customers with the best solutions for automatic thread rolling machine video.

Yes, a thread rolling machine can handle different thread types such as ACO, UNF, or NPT. These machines are designed to be versatile and can be adjusted to produce different thread types by changing the dies or adjusting the machine settings. However, it is important to note that some thread rolling machines may be specifically designed for certain thread types, so it is important to check the machine's capabilities before use.

11.What are the Main Components of a automatic thread rolling machine video?

I have a comprehensive after -sales service system, which can pay attention to market trends in time and adjust our strategy in a timely manner.

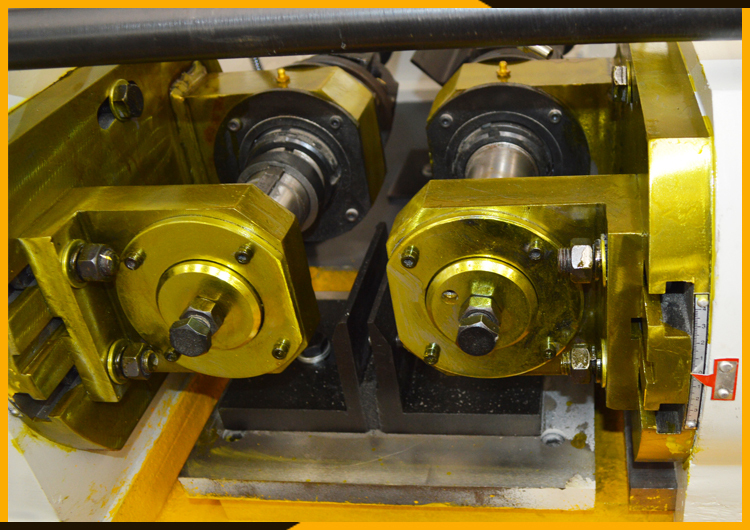

1. Bed: The bed is the main structural component of a thread rolling machine. It provides a stable base for all other components and supports the weight of the machine.

2. Headstock: The headstock is the part of the machine that holds the workpiece and rotates it during the thread rolling process. It also houses the drive mechanism for the workpiece rotation.

3. Tailstock: The tailstock is the part of the machine that supports the other end of the workpiece and provides stability during the thread rolling process.

4. Spindle: The spindle is the rotating shaft that holds the thread rolling dies. It is driven by the headstock and rotates the workpiece during the thread rolling process.

5. Thread Rolling Dies: These are the tools that actually form the threads on the workpiece. They are made of hardened steel and come in various sizes and shapes depending on the type of thread to be rolled.

6. Feed Mechanism: The feed mechanism is responsible for moving the thread rolling dies towards and away from the workpiece. It is usually controlled by a hydraulic or mechanical system.

7. Control Panel: The control panel is where the operator can set and adjust the parameters of the thread rolling process, such as the speed, feed rate, and depth of the thread.

8. Lubrication System: Thread rolling machines require a constant supply of lubricant to reduce friction and heat during the rolling process. The lubrication system ensures that the dies and workpiece are properly lubricated.

12.What are Some Common Applications of Threads Created by a automatic thread rolling machine video?

As one of the top automatic thread rolling machine video manufacturers in China, we take this very seriously.

1. Fasteners: Thread rolling machines are commonly used to create threads on bolts, screws, and other fasteners. This allows for a stronger and more precise thread compared to traditional cutting methods.

2. Automotive Industry: Thread rolling machines are used to create threads on various automotive components such as engine parts, suspension components, and transmission parts.

3. Aerospace Industry: Threads created by thread rolling machines are used in the production of aircraft components such as landing gear, engine parts, and structural components.

4. Construction Industry: Threaded rods and bolts used in construction are often created using thread rolling machines. This ensures a strong and reliable connection between building materials.

5. Medical Industry: Threaded components are used in medical devices such as implants, surgical instruments, and prosthetics. Thread rolling machines are used to create precise and durable threads for these applications.

- Place of Origin:

- Video outgoing-inspection:

- Machinery Test Report:

- Marketing Type:

- Warranty of core components:

- Core Components:

- Key Selling Points:

- Applicable Industries:

- Application:

- Condition:

- Production Capacity:

- Voltage: